The Ultimate Guide to Floating Booms: Water Containment

Effectively managing water surfaces is a critical challenge for businesses and municipal organizations. This includes preventing environmental damage from spills, maintaining clean waterways, or controlling sediment during aquatic construction. The ability to quickly and efficiently contain and control substances on water is not just an operational necessity but also a regulatory and public relations imperative. In today’s environmentally conscious world, effective water surface management is paramount. Businesses and organizations often turn to specialized equipment like floating booms to address a variety of containment and control challenges on water bodies. This guide will provide an in-depth look at these essential tools.

This comprehensive guide will demystify , explore the different types of products available, discuss their practical applications and inherent limitations, and equip you with the knowledge to select the right solution for your specific needs, ultimately guiding you to an informed purchase decision.

Understanding Floating Booms: Your First Line of Defense on Water

What are floating booms used for?

Floating booms are versatile barriers crucial for various marine and aquatic management tasks, serving as a frontline defense against pollution and debris.

- Oil and Chemical Spill Response and Containment: Oil spill floating booms act as a physical barrier to prevent the spread of oil, fuels, or other hazardous liquids on water surfaces. They are crucial for rapid emergency response and minimizing environmental impact. Examples include containing spills in marinas, industrial facilities adjacent to water, or during transport accidents involving tankers or barges.

- Debris and Trash Collection (logs, litter, aquatic vegetation): These booms are effective in directing and collecting floating debris, such as logs, plastics, and nuisance aquatic plants. This protects sensitive areas, maintains clear navigation channels, and prevents damage to infrastructure like power plant intakes and pumping stations.

- Sediment and Turbidity Control in Construction/Dredging Areas: During marine construction, dredging, or pile driving operations, floating booms contain suspended solids and silt. This prevents sediment plumes from impacting ecologically sensitive areas or violating stringent water quality regulations.

- Safety Barriers and Demarcation Lines: Beyond containment, floating booms create visible barriers to restrict access to hazardous zones, such as around active construction sites or spill areas. They also define safe swimming areas, boat exclusion zones, and race perimeters for sporting events.

Defining and Terminology

It is important to clarify that , , and are largely interchangeable terms. They all refer to floating barriers designed to contain or divert substances on water surfaces. Their core function is to create a physical barrier both at the water’s surface and below, preventing the free movement of pollutants or objects.

systems work structurally by leveraging buoyancy to stay afloat while deploying a skirt or barrier below the waterline. This submerged section then contains the target material. Understanding these fundamental principles is key to selecting the appropriate equipment for effective containment strategies. Various NOAA spill containment methods emphasize the critical role of these barriers in environmental protection.

Key Components of a Standard System

Every is composed of several critical parts working together to ensure effective containment and stability.

- Floatation (Buoyancy Chambers/Pontoons): These are the buoyant elements, often air- or foam-filled, that keep the boom afloat. The freeboard (the portion above water) and overall buoyancy determine the boom’s stability and ability to follow waves, crucial for maintaining effective containment.

- Skirt (Below-water barrier depth): The skirt is the submerged part of the boom and acts as the primary barrier to contain oil, debris, or sediment. Its depth is critical and selected based on the type of material being contained and anticipated water conditions, ensuring the material cannot easily pass underneath.

- Ballast (Weights for stability and skirt deployment): Chains or weights are integrated along the bottom edge of the skirt. These ensure the skirt hangs vertically in the water column, enhancing stability and preventing underflow where contained material might escape beneath the boom.

- Connectors and Anchorage Points: Robust mechanisms at the ends of boom sections allow multiple segments to be joined seamlessly to form longer barriers. Attachment points are also present for mooring lines and anchors, which secure the boom in its desired position against currents and environmental forces.

Types of : Matching Solutions to Challenges

Oil Spill

Oil spill are specifically engineered for the critical task of containing hydrocarbons on water.

- Features: These booms typically have a high buoyancy-to-weight ratio to effectively contain oil with minimal freeboard, preventing oil from washing over. They possess excellent chemical resistance to various hydrocarbons and feature robust, quick-connectors for rapid deployment during emergencies.

- Material Variations: Commonly constructed from durable, oil-resistant materials like PVC, Urethane, or rubberized fabrics. These materials are chosen for their impermeability, flexibility, and longevity in harsh marine environments, ensuring they do not degrade when exposed to oil.

- Applications: Essential for emergency oil spill response, they are also used for permanent deployment around potential spill sources like fuel docks and industrial outfalls. Furthermore, they provide continuous protection of sensitive coastal areas and harbors from accidental releases.

Debris and Trash

Designed to manage physical objects rather than liquid contaminants, debris and trash water booms are built for rugged performance.

- Design: These booms often feature a larger freeboard and a stronger, more abrasion-resistant fabric than oil booms. This design helps them withstand the impact and weight of accumulating logs, vegetation, and general litter. They may also incorporate larger floats and heavier ballast for enhanced stability and resistance to impact.

- Usage: Ideal for maintaining clear waterways in rivers, lakes, and marinas, they also protect water intakes for power plants or municipal water systems from blockages. Moreover, they prevent trash accumulation in designated recreational areas, preserving aesthetic appeal and ecological health.

- Distinction from light-duty : These heavy-duty are specifically built for higher tensile strength and impact resistance. This differentiates them from lighter booms designed solely for oil containment or deployment in calm, protected waters, where impact forces are minimal.

Sediment and Turbidity Barriers

These specialized play a vital role in protecting aquatic environments during construction activities.

- Purpose: Sediment and turbidity barriers are specifically designed to prevent the dispersion of silt, sediment, and suspended solids from construction or dredging operations. By doing so, they protect water quality and aquatic ecosystems from harmful particulate matter.

- Specifics: They often feature permeable skirts that allow water flow while retaining solids, which helps reduce pressure on the barrier in flowing water. These barriers require robust anchoring systems to withstand currents and the weight of trapped sediment. Skirt depth is frequently greater than other boom types to reach closer to the seabed, maximizing sediment capture.

Specialized Solutions

Beyond the standard types, numerous specialized solutions cater to unique operational demands.

- Permanent vs. Temporary Booms: Permanent booms are heavy-duty and designed for long-term, continuous deployment with minimal maintenance, ideal for continuous protection. Temporary booms are lightweight, easily deployable, and suitable for short-term spill response or specific project durations, offering flexibility and quick setup.

- Rapid Deployment vs. Long-term Installation: Some are designed for ultra-fast deployment by a small crew, such as air-inflatable booms, which can be crucial in emergency situations. Others require more extensive installation for robust, long-term performance, prioritizing durability and stability over quick setup.

- High-Current and Open Water Designs: Engineered with specialized hydrodynamic shapes, stronger fabrics, and enhanced ballast systems, these booms maintain effectiveness and stability in challenging conditions. They minimize overtopping or underflow even in strong currents, high winds, and significant wave action, crucial for open ocean or turbulent river environments.

Practical Considerations: Deployment, Maintenance, and Limitations

Effective Deployment Strategies for

Proper deployment is essential for a system’s effectiveness and safety.

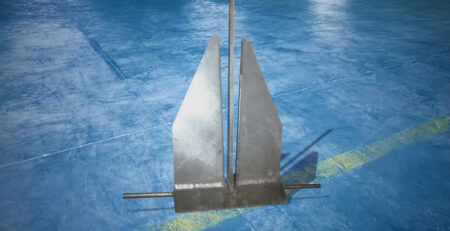

- Anchoring methods (fixed, temporary, tidal): Various anchoring techniques are employed, ranging from permanent mooring systems for long-term installations to temporary anchors like grapple anchors or shore weights for short-term needs. Tidal compensators are also used, which adjust boom height with water level fluctuations, ensuring continuous containment.

- Deployment patterns (U-shape, J-shape, exclusion): Common configurations include U-shapes for collecting contaminants in a central area, J-shapes for diverting material towards a recovery point, and linear exclusion barriers to block off access. Each pattern is optimized for specific containment or deflection goals, maximizing efficiency.

- Safety protocols and personnel training: Emphasizing the importance of trained personnel, proper PPE (Personal Protective Equipment), and adherence to safety guidelines during deployment and retrieval is paramount. This is especially critical in varying water conditions, strong currents, and around marine traffic, preventing accidents and ensuring effective operations.

What are the disadvantages of the floating boom?

While highly effective, floating booms have inherent limitations that must be understood for optimal use.

- Effectiveness limitations in strong currents, high winds, and rough waves: In currents exceeding 0.7-1 knot, oil or debris can be pulled under the boom (underflow), compromising containment. High winds can cause overtopping, where material blows over the boom, while rough waves can cause the boom to pitch and yaw, reducing its effective freeboard and skirt depth, leading to loss of containment.

- Maintenance requirements (cleaning, inspection, repair) for prolonged use: require regular inspection for tears, abrasion, and connector damage to maintain integrity. Cleaning is essential, especially after oil spills or heavy debris accumulation, to prevent material degradation and extend lifespan. This can be a labor-intensive but critical process.

- Installation complexity and cost for large-scale or permanent systems: Deploying extensive or permanent systems can involve significant logistical challenges, requiring specialized equipment such as tugs or workboats. This, along with substantial labor costs, makes the initial setup a considerable investment.

- Potential for overtopping or underflow in severe conditions: Even well-designed have operational limits. Overtopping occurs when material flows over the top of the boom, and underflow happens when it passes underneath. Both lead to containment failure in conditions beyond the boom’s design parameters, highlighting the importance of selecting the right boom for the expected environment.

Material Selection and Durability for Your Investment

The choice of material for your significantly impacts its performance and longevity.

- UV resistance, chemical compatibility, abrasion resistance: These are critical factors influencing a boom’s lifespan. Materials must withstand prolonged sun exposure without degradation, resist corrosive chemicals if used for spills, and endure rubbing against docks, vessels, or debris without puncturing or tearing.

- Longevity and expected service life: Different materials and construction methods offer varying lifespans, directly impacting the return on investment. Heavy-duty, commercial-grade are designed for years of service, providing enduring protection, whereas lighter, temporary booms are intended for shorter operational periods.

- Storage and transportation considerations: The ease of folding, rolling, or packing for storage and transport is important for rapid response scenarios and minimizing the storage footprint. Compact, easily deployable designs reduce logistical burdens and ensure the boom is ready when needed.

Making an Informed Purchase: Factors for Your Solution

Matching to Your Specific Environment

The effectiveness of your depends heavily on its suitability for the intended environment.

- Calm lakes, slow-moving rivers, busy harbors, or open ocean: The operational environment dictates boom characteristics. Calm water allows for lighter-duty booms, while high currents and waves demand robust, high-freeboard, and deep-skirt designs with strong ballast to maintain stability and prevent escape.

- Type and volume of contaminant/debris to be controlled: Whether dealing with a light sheen versus heavy crude oil, or small litter versus large logs, the nature of the material to be contained directly influences the boom’s material, buoyancy, and structural strength requirements.

- Duration of deployment (temporary vs. permanent): Assess if the boom is for a one-time emergency, a short-term project, or a long-term protective barrier. This assessment influences the choice between durable, high-investment permanent booms and more economical, quick-response temporary solutions.

Customization and Accessory Options for Your

Enhancing your system with accessories can significantly improve its functionality and safety.

- Connector types, anchor kits, tidal compensators, lights, and markers: Explore how different connector styles (e.g., ASTM, universal slide) impact interoperability with other boom sections. The necessity of appropriate anchor kits for varied seabeds, and accessories like warning lights or navigational markers, enhance visibility and safety, especially in low light or busy areas.

- Integration with skimmers, pumps, or other response equipment: Consider designed to integrate seamlessly with other spill response tools. This includes oil skimmers or vacuum pumps, which are crucial for forming a complete and efficient containment and recovery system, maximizing cleanup efforts.

Understanding Pricing and ROI for Your Investment

A represents an investment, and understanding the financial implications is key to making a smart decision.

- Initial purchase cost vs. long-term durability and effectiveness: Evaluate the upfront cost against the expected lifespan, maintenance requirements, and overall performance. A higher initial investment in a durable can lead to significant long-term savings in replacement costs and improved environmental protection by preventing costly spills.

- Rental vs. outright purchase considerations: For infrequent or short-term needs, renting can be a cost-effective option, avoiding storage, maintenance, and capital outlay. However, for regular or critical operations, purchasing offers immediate availability, customization, and long-term asset value.

- Installation, maintenance, and storage costs: Factor in the total cost of ownership, which includes the expense of deploying, regularly inspecting, cleaning, repairing, and securely storing the system throughout its operational life. These ongoing costs are crucial for budgeting and maintaining peak performance.

Conclusion

Choosing the right is a strategic decision demanding careful consideration of intended use, environmental conditions, and specific features. From robust oil containment for spill response to heavy-duty for debris management and precise solutions for turbidity control, the market offers a diverse array of options. A well-chosen floating containment boom is an invaluable asset for effective water surface management, safeguarding environments, and ensuring operational compliance.

Don’t compromise on your water containment needs. Contact our experts today for a personalized consultation to discuss your specific requirements, request a tailored quote for our high-quality products, or explore our comprehensive range of designed for every application. Let us help you find your ideal water containment solution.