Methods and emergency measures for oil spill response

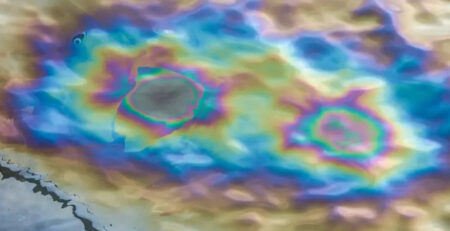

Localization of oil products and crude oil spills

Booms are the means of localization and liquidation of oil and oil products spills in water areas. Important functions of booms are: prevention of oil spreading on the water surface, reduction of oil product concentration to facilitate cleanup, and trawling (diversion) of oil away from environmentally sensitive areas.

Barrier booms are subdivided into: deflecting booms (oil-deflecting booms BN) – to protect the shore from oil and oil products and fence them off; sorbing booms (sorbing booms BSS) – absorbing oil and oil products; inflatable booms – allowing their quick deployment in water areas; heavy inflatable booms – fencing a tanker at the terminal.

Once the oil spill is localized, the next step is to clean up the spill.

Methods of oil product and crude oil spill response

There are several methods of oil spill containment: thermal, mechanical, biological, and physical-chemical. The main method of oil spill cleanup is mechanical collection of oil products. This method is most effective at the very beginning of a spill, because the thickness of the oil layer remains large. Mechanical recovery is difficult when the spreading area is large, the oil layer thickness is small, and there is constant movement of the surface layer under the influence of wind. This makes it difficult to use this method. Complications may also arise when cleaning ports and shipyards from oil products, they are usually contaminated with various debris, boards, wood chips and various objects floating on the water.

Thermal method is used in case of large thickness of oil layer after pollution before the beginning of emulsion formation with water. The method is based on burning of the oil layer. It is well enough combined with other methods of spill liquidation.

Mechanical method. An example of such a method is the collection of oil product by skimmers.

Oil skimming devices, or skimmers, are designed to collect oil directly from the water surface. Depending on the type and quantity of spilled oil products and weather conditions, different types of skimmers are used, both in terms of design and principle of operation.

According to the method of movement or fixing oil skimmers are divided into self-propelled, installed stationary, towed and portable on various watercrafts. According to the principle of action – on threshold (PN – threshold oil skimmer), oleophilic (CO – oleophilic skimmer), vacuum (UVM) and hydrodynamic.

The physical-chemical method uses dispersants and sorbents and is effective when mechanical collection is impossible, for example, when the film thickness is small and when the spilled oil slick poses a real threat to environmentally sensitive areas. Sorbents in contact with oil begin to absorb it immediately, the saturation period is reached in the first ten seconds (assuming an average density of oil products). They form clumps of material that are saturated with oil to a maximum.

In cases of oil slick movement towards protected areas, dispersants are used. They are special chemical substances that break down the oil film and prevent it from spreading further. However, it should be taken into account that dispersants can have a negative impact on the environment.

Biological method is used after physical-chemical and mechanical methods at a layer thickness of at least 0.1mm. The technology of treatment of oil-contaminated water and soil – bioremediation, it is based on the use of special, microorganisms on the basis of hydrocarbon oxidation or biochemical preparations. The number of microorganisms capable of producing assimilation of petroleum hydrocarbons is small. They are mainly bacteria, representatives of the genus Pseudomonas, and some species of fungi and yeasts. At sufficient oxygen saturation of water and at a temperature of 15-20% Cº, these microorganisms are capable of oxidizing petroleum products at a rate of 2g/sq. m. of water surface per day. However, bacterial oxidation at low water temperatures is slow and oil products remain in water bodies for a long time – up to 50 years.

When choosing a method of oil product spill elimination one should remember the following: when carrying out works on accident elimination the main factor is the time factor, trying not to cause the greatest ecological damage than the existing oil spill.