Industrial Oil Skimmers: Key to Efficient Manufacturing Processes

In modern manufacturing, maintaining cleanliness and efficiency is crucial for product quality and workplace safety. One of the most effective solutions for combating oil contamination in industrial processes is the use of industrial oil skimmers. These devices are designed to remove oil, grease, and other hydrocarbons from the surface of liquids used in manufacturing.

Types of Oil Skimmers and Their Characteristics

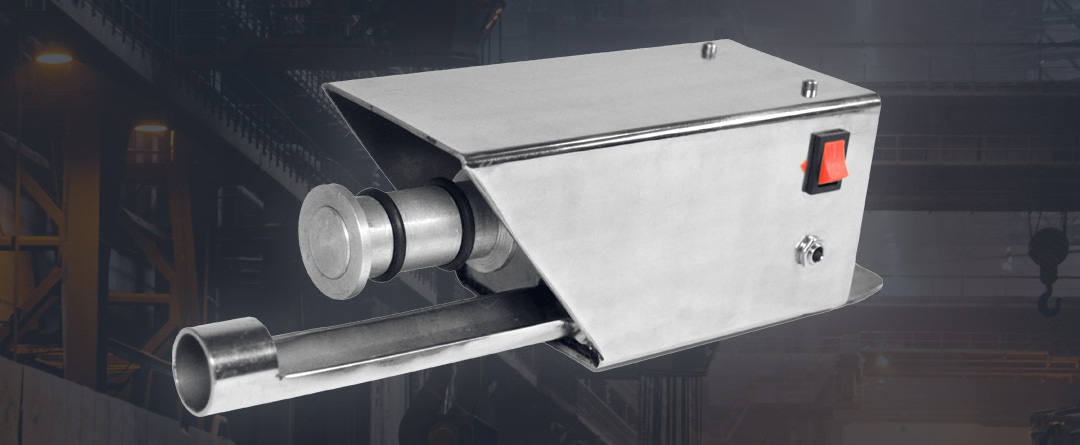

- Belt Oil Skimmers: Utilize an endless belt that immerses into the liquid, attracting oil and lifting it for collection. Suitable for various types of oils and viscosities.

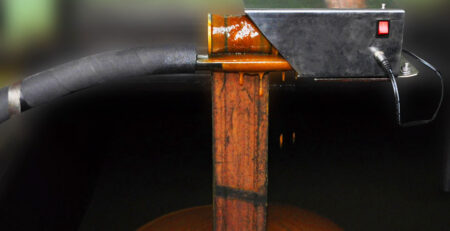

- Tube Oil Skimmers: Employ a continuous loop of tubing that dips into the liquid, attracting oil through its oleophilic surface and conveying it for collection. Highly efficient and ideal for large tanks. Versatile in handling different oil types and viscosities.

- Disc Oil Skimmers: Use rotating discs to collect oil from the liquid surface. Effective for removing oil from extensive surfaces.

- Weir Skimmers: Floating units that allow oil to flow over a weir edge into a collection sump by positioning the edge below the slick surface. Suitable for large-scale oil removal operations.

Applications of Oil Skimmers in Manufacturing Processes

- Wastewater Treatment: Oil skimmers are employed to remove oil and grease from wastewater, reducing the load on treatment facilities and improving purification quality.

- Coolant Treatment: In metalworking, oil skimmers help eliminate oil from coolants, extending their lifespan and enhancing processing quality.

- Food Industry: Used to remove fats and oils from process liquids, ensuring equipment and product cleanliness.

- Automotive Workshops: Assist in removing oil and lubricants from cleaning solutions, reducing disposal costs and improving environmental metrics.

Advantages of Using Oil Skimmers

- Cost Savings: Reduce expenses associated with disposing of contaminated liquids and extend the lifespan of process fluids.

- Improved Product Quality: Ensure cleanliness in manufacturing processes and equipment.

- Compliance with Environmental Standards: Lower emissions of pollutants into the environment.

- Enhanced Workplace Safety: Decrease the risk of accidents due to slippery surfaces and contaminated equipment.

Conclusion

Industrial oil skimmers are indispensable components of modern manufacturing processes, providing effective removal of oil and grease from process liquids. Selecting the appropriate type of oil skimmer depends on the specific manufacturing requirements and contamination characteristics. Implementing these devices contributes to increased production efficiency, cost reduction, and improved environmental performance of the enterprise.

For additional information and to select the optimal solution for your production needs, we recommend consulting with specialists from “ECONADIN” or visiting their website.