Industrial oil separators: a revolution in production

In the dynamic world of manufacturing, efficiency and sustainability are paramount. Enter industrial oil skimmers—innovative devices designed to remove unwanted oils, greases, and hydrocarbons from liquids like water, coolants, and cleaning solutions. These unsung heroes of industry not only enhance equipment performance but also help businesses meet environmental standards with ease.

Industrial oil separators That Work Smarter, Not Harder

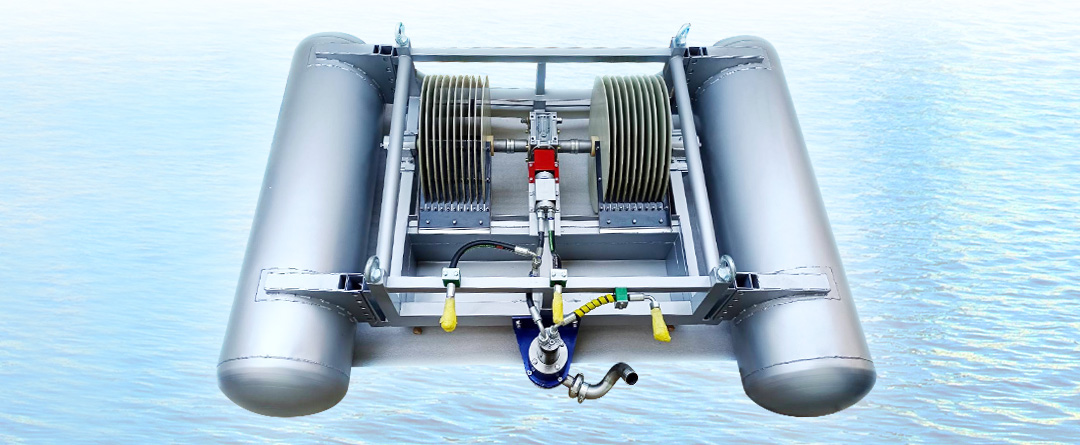

- Belt Skimmers: Imagine a continuous belt gliding effortlessly through contaminated liquids, drawing oil to its surface like a magnet. Belt skimmers are the ultimate multitaskers, adaptable to various oil types and operating conditions.

- Tube Skimmers: Compact and efficient, these skimmers use a floating tube to sweep across liquid surfaces, capturing oil even in hard-to-reach tanks. They’re the perfect solution for irregularly shaped containers.

- Disk Skimmers: Sleek and effective, these rotating disks skim thin oil layers with precision. A simple wiper system removes the oil, ensuring clean and efficient collection.

What Makes Them Essential?

- Durable and Compatible: Built with corrosion-resistant materials, skimmers are tough enough to withstand harsh industrial environments.

- Efficient Oil Removal: Designed to target oil without capturing excess water, skimmers reduce waste volume and disposal costs.

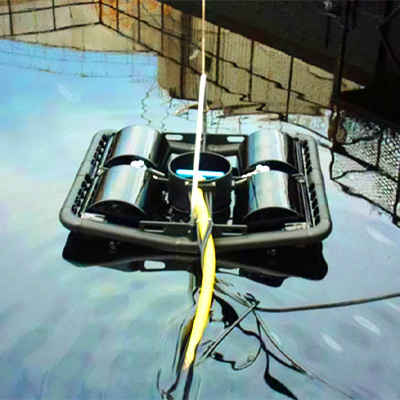

- Flexible Installation: From tanks to open water surfaces, skimmers fit seamlessly into existing systems with minimal effort.

- Low Maintenance: High-quality skimmers are engineered for simplicity, minimizing downtime and keeping operations running smoothly.

Where Do Skimmers Shine?

- Metalworking Marvels: Keep coolant systems free of tramp oils to prevent bacterial growth and extend coolant life.

- Parts Washing Perfection: Ensure cleaner components by removing oils from parts washing systems, reducing solution replacement frequency.

- Wastewater Wonders: As a preliminary treatment, skimmers cut down oil content in wastewater, paving the way for efficient processing.

- Food Industry Friend: From fats to greases, skimmers help food processing plants meet strict environmental discharge regulations.

Why Every Industry Needs One?

- Eco-Friendly Operations: Skimmers support environmental compliance by effectively managing oil waste.

- Cost Efficiency: Say goodbye to frequent maintenance costs and hello to extended fluid lifespans.

- Top-Quality Products: Cleaner fluids mean higher-quality outputs, ensuring customer satisfaction.

- Safety First: By removing oil from work areas, skimmers reduce slip hazards, fostering a safer work environment.

The Takeaway

Industrial oil separators aren’t just tools; they’re investments in sustainability, efficiency, and safety. Whether you’re working with coolants, wastewater, or even food processing, there’s a skimmer solution tailored to your needs. Ready to transform your manufacturing process? Explore more at Econadin’s official website and discover the difference these devices can make.