To effectively remove coal dust from the water surface, it is recommended to use the PortiBin floating head threshold skimmer. This innovative solution allows collecting coal slurry (a mixture of coal dust, organic and inorganic contaminants and water) with minimal capture of clean water, which significantly increases the efficiency of the water area cleaning process.

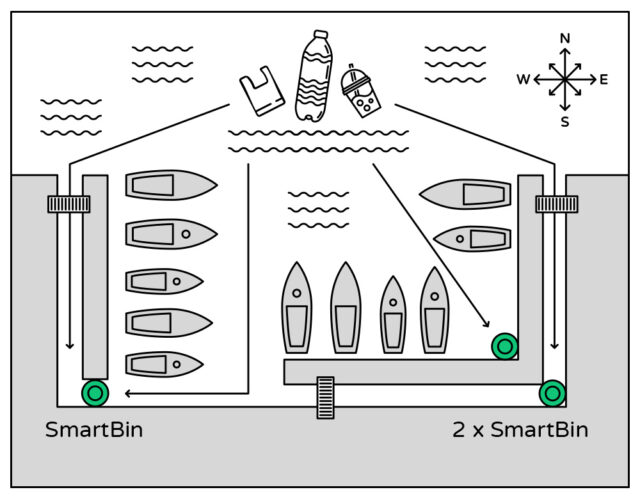

Operating principle of the PortiBin system

The PortiBin design is connected to a powerful motorized pump that sucks water into the PortiBin tank and pumps it back into the pool. The filtration process removes debris, coal and grit dust, oil film and other contaminants that remain in a special collector-filter. Filters are replaced as they fill up.

Collected waste such as plastic bottles, bags and other contaminants can be sent for recycling and reuse.

Main features of PortiBin

- Garbage collection: from 5 to 20 kg (depending on the type and form of dirt).

- Power supply: operates from 220 V mains.

- Equipment: includes a motor pump for water pumping.

- Environmental efficiency: the collected waste can be disposed of for recycling.

Advantages of using PortiBin

- High throughput – efficient collection of contaminants.

- Reliable and durable – resistant to long term use.

- Ease of use – easy to install and maintain.

- Effective in “problem” areas – installed in areas where debris is most likely to accumulate.

Where does PortiBin apply?

- Offshore areas

- Floodplains and reservoirs

- Swimming pools and hydraulic structures

- Yacht clubs and marinas

- Grain and coal terminals

PortiBin+ is an advanced modification, additionally equipped with special filters for collecting coal and grain dust, as well as iridescent oil film from the water surface. This solution makes ports and water areas cleaner, improving the environmental situation and increasing the attractiveness of water bodies.

Key elements of the PortiBin system

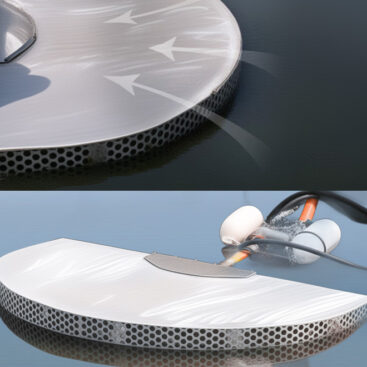

- Threshold skimmer with floating head

– Installed with minimum burial below the water surface.

– Provides effective collection of surface contaminants.

– Minimizes contaminant-to-water ratio, reducing the volume of water requiring further treatment.

– Alternative skimmers (drum, lint, etc.) are inferior due to poor contaminant adhesion. - Enhanced slurry transport with ejector

– Uses a water-water ejector connected to the skimmer’s slurry removal connection.

– Increases contaminated water pumping capacity with low energy consumption.

– Reduces operating costs due to reduced abrasion of pumping equipment.

– Provides stable slurry transportation to the separator tank. - Separator tank (gradient sand trap separator)

– Coarsely filters and dewaters the water-coal dust mixture.

– Equipped with threshold separation, coalition or mesh filters.

– Includes film collection of floating particles and a solids settling separator.

– Allows partially treated water to be returned back to the reservoir for additional sedimentation.

– Includes a floating dust film separation unit.

– Provides water reuse by feeding recycled process water to the ejector.

Thanks to its versatility and environmental efficiency, the PortiBin system can effectively clean water areas from debris, coal and grain dust, and oil contamination, reducing water loss and operating costs.