The Essential Role of an Oil Containment Curtain Boom

Oil spills pose an immediate and critical threat, causing widespread environmental devastation, disrupting commercial operations, and harming coastal communities. Effective containment solutions are essential to protect sensitive ecosystems and prevent economic disaster. This is where the oil containment curtain boom becomes an indispensable tool. It is a highly effective, versatile, and essential component in modern spill management strategies. Its inherently flexible oil spill boom design allows for exceptional performance across diverse aquatic environments, including challenging rougher, open water conditions. This article will comprehensively explore why these booms are a preferred and vital choice for both commercial and industrial spill response scenarios.

Understanding the Oil Containment Curtain Boom: Design and Function

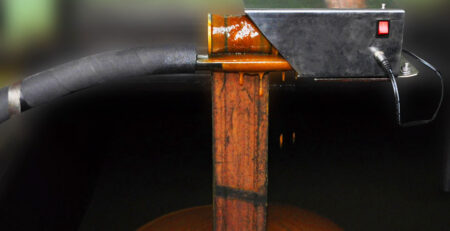

An oil containment curtain boom is a specialized floating curtain barrier engineered to create a physical obstacle on the water’s surface. Its primary purpose is to prevent or limit the spread of oil and other pollutants. By doing so, it effectively concentrates the spilled material, making recovery efforts significantly easier and more efficient.

A curtain boom is designed with several essential structural parts that enable its effective operation:

- Flotation: This buoyant upper section ensures the boom remains afloat and stable on the water surface. It maintains adequate freeboard, which is the portion of the boom extending above the waterline.

- Tension Member: A strong, integrated line, often a chain or cable, runs along the boom’s entire length. This member provides crucial structural integrity, absorbing external forces from currents or towing vessels without stretching or deforming the boom.

- Skirted oil boom (Sub-surface skirt): This is the crucial vertical fabric barrier extending below the water line. It is responsible for trapping and containing the oil beneath the surface, effectively preventing it from escaping underneath the boom.

- Connectors: Robust end connectors allow multiple boom sections to be securely joined together. This enables the formation of longer, continuous containment barriers that can adapt to the size of any spill.

The fundamental principle of how a curtain boom operates involves creating a physical barrier on the water surface. It can be deployed in various ways: to encircle a spill entirely, to deflect oil away from sensitive areas like shorelines or wildlife habitats, or to funnel it towards specific recovery points where specialized equipment can collect the contained oil.

Key Advantages: Why Flexible Curtain Booms are Superior

The design and features of oil containment curtain boom solutions offer distinct advantages, making them superior for effective spill response.

- Optimal Flexibility: The flexible oil spill boom design is critical for its performance. This flexibility allows the boom to naturally conform to the contours of waves and dynamic water conditions, ensuring continuous contact with the water surface. This continuous contact is vital for preventing oil from escaping underneath the boom, even in agitated waters. These flexible boom designs are specifically engineered to conform to dynamic water environments, maximizing containment.

- High Buoyancy-to-Weight Ratio: This is a crucial feature. A high buoyancy-to-weight ratio means the boom possesses excellent stability and significant freeboard while remaining relatively light. This characteristic allows the boom to perform exceptionally well in rougher, open water conditions, resisting swamping by waves and maintaining its containment integrity against strong wave action.

- Lightweight Design and Ease of Handling: A lightweight construction offers significant benefits, directly addressing the ease of handling for spill responder crews. This design facilitates rapid deployment, which is crucial in time-sensitive emergencies. It also reduces the number of personnel required for installation and retrieval, minimizing logistical challenges and saving valuable time during critical situations.

- Durability and Robustness: High-quality, durable materials, such as PVC or Urethane coated fabrics, are used in their construction. These materials are UV-resistant, oil-resistant, and tear-resistant. This robust construction ensures that the oil containment curtain boom can withstand harsh marine environments, prolonged exposure to various types of oil, and challenging weather conditions, guaranteeing a long service life.

- Effective Containment: The depth of the skirted oil boom design, combined with its inherent flexibility and stability, ensures maximum containment efficiency. This is vital for a wide range of oil types and viscosities, preventing dispersion and facilitating successful recovery operations.

Versatile Applications: Where These Booms Make a Difference

The versatility of the curtain boom makes it invaluable in a wide array of environments and scenarios.

- Ports, Harbors, and Sheltered Waters: These booms are highly suitable for controlled and semi-controlled environments. Their ease of deployment and effectiveness make them ideal for containing spills in confined spaces around docks, piers, during fuel transfer operations, and within sensitive coastal estuaries.

- Open Water and Offshore Environments: The robust design, high buoyancy, and stability of these booms make them ideally suited for more challenging open water conditions. This includes deployment around offshore oil platforms, for coastal protection during maritime incidents, and in large-scale open sea containment operations, directly addressing a key search intent for users needing solutions for harsher conditions.

- Industrial Spill Response: Beyond marine environments, these booms are indispensable in industrial settings. They are used in refineries, power plants, manufacturing facilities, and construction sites for containing accidental spills of oil, chemicals, or other pollutants. They prevent contaminants from spreading within the facility’s perimeter or from reaching public waterways, directly connecting to the overall commercial and informational intent of businesses seeking spill prevention solutions.

- Emergency Preparedness and Long-Term Deployment Scenarios: Curtain boom systems play a vital role in proactive environmental protection. They are deployed as pre-emptive defenses around vulnerable assets, for containment during maintenance work that poses a spill risk, or as part of long-term environmental protection strategies to safeguard waterways.

Choosing the Right Oil Containment Curtain Boom for Your Needs

Selecting the appropriate oil containment curtain boom is crucial for ensuring optimal performance and cost-effectiveness for specific operational requirements. Several critical factors must be considered:

- Water Conditions: Assess the typical current speed, expected wave height, and the potential presence of debris. This will determine if you need a boom designed for calm, sheltered waters or more demanding open water conditions.

- Expected Spill Volume and Type: The anticipated quantity and viscosity of the pollutant will help determine the appropriate boom strength, material, and crucial skirt depth needed for effective containment.

- Deployment Requirements: Consider available equipment, the number of personnel, and the desired speed of deployment and retrieval. Lightweight, easily deployable options are often preferred for rapid response.

- Storage and Maintenance: Evaluate the ease of storage, the boom’s inherent durability, and the long-term maintenance needs to ensure its readiness for future use.

It is paramount to choose a flexible oil spill boom with a high buoyancy-to-weight ratio for optimal performance, especially when there’s a possibility of encountering rougher, open water conditions. This characteristic directly impacts its ability to contain spills effectively in challenging environments.

Conclusion: Secure Your Operations with Advanced Oil Containment Solutions

The oil containment curtain boom stands as an indispensable and highly effective tool for comprehensive oil spill response. Its unique design, combining flexibility, high buoyancy, and robust construction, allows it to perform reliably across diverse aquatic environments, from sheltered harbors to open water. These characteristics, coupled with its ease of handling and durability, reaffirm its status as a superior solution.

Investing in these advanced containment solutions is critical for protecting the environment, mitigating financial losses, and ensuring the operational continuity and reputation of businesses and industries. We encourage all commercial entities, industrial facilities, and spill response organizations to proactively explore and invest in curtain boom solutions tailored to their specific needs. Preparedness is key to securing your operations and safeguarding our invaluable natural resources.