Oil Containment Booms: Your First Line of Defense Against Spills

Oil spills pose a constant threat to our planet’s marine ecosystems, the livelihoods of coastal communities, and the global industries that rely on healthy waters. These incidents cause devastating environmental and economic damage. In the face of such emergencies, oil containment booms emerge as the immediate and most vital line of defense. They are essential oil spill containment barriers that play a critical role in both emergency response and preventative strategies.

This guide explores what these crucial barriers are, how they function, the different types available, their diverse applications, and the profound benefits of their deployment for effective spill management. Understanding their role is key to protecting our precious water resources.

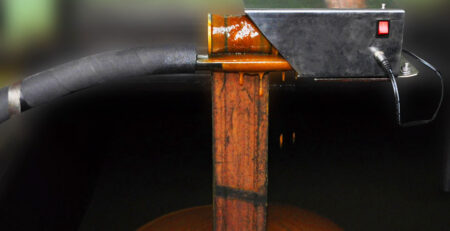

An oil containment boom is a specialized floating physical barrier. Its purpose is to restrict the movement and spread of oil and other pollutants on water surfaces, stopping further contamination. Its fundamental role is to act as a physical oil spill containment barrier. It does this by creating a floating wall that gathers, diverts, or holds spilled oil. This allows for easier recovery and prevents the oil from reaching sensitive areas.

Effective oil booms consist of several key structural parts:

- Flotation: These are buoyant elements, such as air chambers or foam, that keep the boom afloat on the water’s surface.

- Freeboard: This is the part of the boom that extends above the waterline. Its job is to prevent oil from washing over the top of the boom.

- Skirt (or Draft): This is the submerged section of the boom. It is designed to stop oil from escaping underneath the barrier.

- Ballast: These are weights along the bottom edge of the skirt. They keep the boom stable and vertical in the water, even in moving currents.

Understanding these boom structure components is crucial for making sure a boom works well in different marine conditions. The principle behind their effectiveness is simple: oil is less dense than water, so it floats. This characteristic makes a floating barrier highly effective at containing a spill.

Types of Oil Containment Booms: Tailored Solutions for Every Scenario

There are many different categories of oil containment booms. The best choice always depends on the specific environmental conditions and the type of spill.

- Fence Booms: These booms have a flat panel design. They are best suited for calm, protected waters where currents are very weak. They are simple to use and easy to put in place.

- Curtain Booms: These feature a strong, continuous skirt that goes deeper below the waterline. This design makes them good for choppy waters, moderate currents, and more challenging marine settings.

- Inflatable Booms: Designed for quick setup and compact storage, these floating booms for oil are filled with air right at the spill site. They offer great flexibility for emergency response but need special inflation gear.

- Solid Flotation Booms: These booms are built with internal foam or solid buoyant parts. They are known for being very durable and are often used as an oil barrier for long-term use in permanent setups or busy areas.

Boom materials are typically durable, oil-resistant fabrics like PVC or urethane. It’s important that these materials resist UV light, are compatible with different chemicals, and have strong connectors. These features ensure long-lasting use and good performance in harsh environments.

Critical Applications: Where Marine Oil Spill Booms Make a Difference

Marine oil spill booms are vital tools used in many different and important ways. They make a real difference in protecting our waters.

- Ports and Harbors: These booms are essential for containing possible spills from ships or fuel transfers. A strong boom for ports and harbors protects busy shipping lanes, docking areas, and sensitive waters close to shore from pollution.

- Coastal Protection: Booms are placed around beaches, estuaries, mangrove forests, and wetlands. This protects delicate ecosystems and important tourist spots from arriving oil slicks.

- Industrial Facilities: Permanent or easily deployed booms are crucial around places like refineries, power plants, oil terminals, and offshore drilling platforms. They stop local spills from spreading into open waters.

- Open Water Spills: Large, heavy-duty marine oil spill booms are deployed in oceans, large lakes, and rivers to contain big spills. They are often used with skimmers (devices that remove oil) and dispersants (chemicals that break up oil).

- Preventative Measures vs. Emergency Response: Booms have a dual role. They are used proactively around potential spill sources to prevent incidents. They are also rapidly deployed during emergencies for quick containment and recovery.

The Unseen Benefits: Why Investing in Quality Oil Containment is Crucial

Investing in a durable oil barrier for long-term use offers benefits far beyond simply containing a spill. It’s a smart, strategic decision with wide-ranging positive impacts.

- Environmental Safeguard: Booms minimize harm to the environment. They protect marine life, birds, and key habitats like coral reefs and wetlands from oil’s toxic effects, helping to keep biodiversity safe.

- Economic Impact Mitigation: By containing spills, booms significantly cut down on costly clean-up operations. They protect commercial fishing, aquaculture, tourism industries, and local economies that rely on clean water.

- Regulatory Compliance and Reputation: Using effective containment helps businesses meet strict environmental rules and avoid hefty fines. It also protects a company’s good name and builds public trust.

- Enhanced Safety: Booms help create safer operations by controlling dangerous materials. They protect workers involved in spill response and reduce the risk of widespread contamination.

The long-term value of a quality oil barrier for long-term use is clear. It ensures continuous readiness and greatly reduces the overall risks associated with spills.

Choosing the Right Oil Containment Boom: Key Considerations

Selecting the correct oil containment booms requires careful thought. Here are the key factors to evaluate:

- Type of Oil: Consider how thick the oil is (viscosity). Light fuels behave differently than heavy crude oil, which affects how it interacts with the boom material.

- Spill Size and Duration: Larger spills or situations with long-term risks will need more robust and extensive boom systems.

- Water Conditions: You must assess currents, wave height, wind speed, and water depth. These factors determine the necessary freeboard, skirt depth, and overall strength of the boom.

- Deployment Speed and Logistics: Think about how quickly the boom can be put into action, its weight, and storage needs for emergency situations.

- Durability and Maintenance: It is vital to choose an oil barrier for long-term use made from high-grade, UV-resistant, and chemically compatible materials. This ensures it can withstand harsh marine conditions and lowers replacement costs.

- Cost-Effectiveness: Balance the initial cost with the boom’s long-term performance, durability, ease of upkeep, and the potential money saved from effective spill prevention and control.

Conclusion: Safeguarding Our Waters with Effective Oil Containment

Oil containment booms are an indispensable part of environmental protection and emergency readiness for any operation near water. These specialized barriers are incredibly versatile and critical for reducing the environmental, economic, and social impacts of oil spills across many different uses. Investing in the right oil containment booms and staying prepared is more than just meeting a rule. It’s a crucial promise to protect our valuable marine resources for generations to come.