The Essential Guide to Oil Absorbent Materials: Types and Uses

Oil spills pose a constant threat across various industries, from manufacturing plants to transport hubs and marine operations. Such incidents can cause severe environmental damage, endanger workers, and incur hefty financial penalties for businesses. This highlights the critical need for effective solutions. Oil absorbent materials are specialized products engineered precisely for this purpose. They selectively absorb oils and other petroleum-based liquids while effectively repelling water. These materials play an indispensable role in environmental protection, enhancing workplace safety, and ensuring efficient spill response for businesses of all sizes. They come in a diverse range of specialized forms, such as pads, rolls, booms, and socks, each designed with unique structures for specific applications.

The Science Behind Oil Absorbency

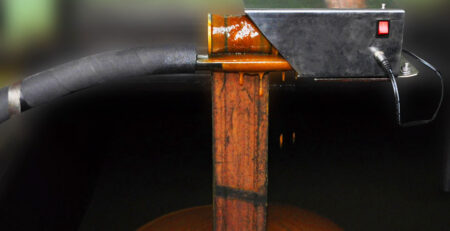

Understanding how oil absorbent materials work reveals their ingenious design. The fundamental principle lies in their unique properties: they are inherently oleophilic, meaning they actively attract and bond with oil, and simultaneously hydrophobic, which means they repel water. This dual characteristic is crucial. It allows the materials to selectively soak up oil molecules, preventing water absorption even when a spill occurs on a wet surface or in water.

Many high-performance absorbents are manufactured using synthetic materials, primarily polypropylene. Polypropylene is highly efficient due to its fine fiber structure and specific chemical properties, which create a large surface area for oil to cling to. Beyond synthetics, natural fiber alternatives also exist. These include materials like peat moss, cellulose, and corn cob. These natural options offer advantages such as biodegradability, and their unique internal structures also provide ample surface areas for effective oil capture.

Key Types of Oil Absorbent Materials and Their Applications

Effective spill response relies on choosing the right tool for the job. Various specialized oil absorbent materials are available, each designed for specific containment and cleanup scenarios. Understanding their distinct features and common uses is vital.

Oil Absorbent Pads

Oil absorbent pads are versatile, flat sheets often made from melt-blown polypropylene. They are available in various weights, from light to heavy, and a range of sizes to suit different needs. Their construction is typically dimpled or bonded. This design increases their durability, enhances tensile strength to prevent tearing, and boosts wicking speed for faster absorption.

- Applications:

- Wiping up small drips and spills on shop floors or work surfaces.

- Lining workbenches, shelves, or storage areas to catch leaks.

- Placing under leaky equipment or machinery during routine maintenance.

- General shop floor cleanup to maintain a safe and clean environment.

Oil Absorbent Rolls

Oil absorbent rolls are essentially large, continuous versions of absorbent pads. They are designed for covering extensive areas or for creating customized absorbent mats. These rolls are typically perforated every few inches, allowing users to easily tear off specific lengths as needed. This feature helps significantly in minimizing material waste and customizing coverage for particular areas or equipment.

- Applications:

- Covering long walkways or aisles in industrial facilities to prevent slip hazards.

- Protecting large manufacturing lines from continuous drips and leaks.

- Absorbing spills in high-traffic areas where large coverage is required.

- Creating bespoke absorbent solutions tailored to unique equipment footprints or irregular spaces.

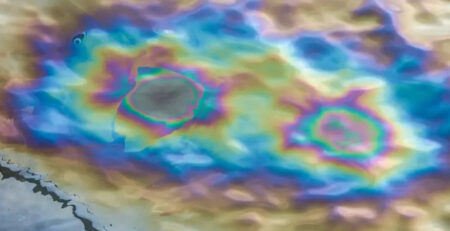

Oil Absorbent Booms

Oil absorbent booms are long, cylindrical barriers filled with highly oleophilic absorbent material. They are specifically engineered for containment on both water and land. Their robust outer mesh or netting effectively retains the absorbent filler, ensuring it stays intact even in challenging conditions. Many booms also feature sturdy clips or rings at each end. These allow for linking multiple booms together to form longer, uninterrupted containment perimeters.

- Applications:

- Primary role: Containing and absorbing large oil spills on water bodies like rivers, lakes, or oceans to prevent widespread environmental damage.

- Encircling machinery or drums on land to prevent leaks from spreading across floors.

- Surrounding storm drains to protect waterways from hazardous runoff during a spill.

Oil Absorbent Socks

Oil absorbent socks are flexible, tube-like absorbents, typically filled with a granular or fibrous absorbent material. They are designed primarily for land-based containment and absorption. Their pliable nature is a key feature, allowing them to conform easily to irregular shapes, fit into tight spaces, and create effective barriers around equipment bases. To understand the various product types and their key distinguishing structures, it’s essential to look at the manufacturing details.

- Applications:

- Surrounding leaky machinery to absorb drips and prevent spread.

- Diverting liquids away from sensitive areas, equipment, or drains.

- Absorbing spills along walls, in corners, or in other confined spaces.

- Acting as a perimeter containment for spills on land where irregular shapes are a factor, offering a snug fit.

Choosing the Right Oil Absorbent Material for Your Needs

Selecting the most appropriate oil absorbent materials for a given situation is a critical decision that impacts spill response effectiveness and safety. Several key factors should be carefully considered.

First, evaluate the spill size and location. Larger spills, especially those occurring on water, necessitate specialized solutions like oil absorbent booms for containment and absorption. In contrast, smaller, land-based spills might be more efficiently managed with oil absorbent pads for quick cleanup or oil absorbent socks for perimeter control.

Second, always confirm the type of liquid involved. While this post focuses specifically on oil-only absorbents designed for petroleum products, it is crucial to ensure the chosen material is indeed formulated for oils and not universal liquids, which absorb water as well. Using the wrong absorbent can lead to ineffective cleanup.

Third, consider the absorbency capacity. Always check the product’s absorption rate and total capacity (often measured in gallons per bale or roll). This ensures you have sufficient material readily available for the potential spill volume, preventing shortages during an emergency.

Finally, think about reusability and disposal. Most oil-only absorbents are designed for single-use due to safety and contamination concerns. Proper, compliant disposal of saturated absorbents is essential to prevent further environmental harm and adhere to regulations. Matching the unique structure and intended application of oil absorbent pads, oil absorbent rolls, oil absorbent booms, and oil absorbent socks to the specific spill scenario optimizes cleanup efficiency and enhances overall safety.

Benefits of Utilizing Specialized Oil Absorbents

The strategic use of dedicated oil absorbent materials offers substantial benefits for businesses and the environment alike.

- Environmental Protection: Employing specialized absorbents prevents harmful hydrocarbon pollutants from contaminating soil, protecting delicate waterways, and preserving vital aquatic and terrestrial ecosystems. This proactive approach minimizes ecological damage from spills.

- Regulatory Compliance: The effective use of these materials helps businesses adhere to strict environmental regulations, such as EPA guidelines and local ordinances. Compliance avoids significant fines, legal repercussions, and reputational damage.

- Enhanced Workplace Safety: Specialized absorbents substantially reduce slip-and-fall hazards caused by oily surfaces. They also help improve indoor air quality by containing volatile organic compounds (VOCs) released from spills, contributing to a much safer overall working environment for employees.

- Cost Savings: Preventing expensive property damage to facilities and machinery breakdowns due to leaks leads to considerable long-term financial benefits. Avoiding the high costs associated with professional environmental remediation further emphasizes the economic advantage of proactive spill management.

- Improved Efficiency in Spill Response: Having the right specialized tools readily available leads to significantly faster containment and cleanup times. This minimizes operational downtime, ensures business continuity, and allows for a swift return to normal operations after an incident.

Conclusion

Understanding the diverse world of oil absorbent materials is comprehensively important, as they play a pivotal role in modern spill management strategies. Selecting the appropriate type, whether it be oil absorbent pads for minor drips, oil absorbent rolls for covering large areas, oil absorbent booms for water containment, or oil absorbent socks for land-based perimeters, is paramount. This informed selection is crucial for achieving effective, efficient, and safe spill response. Ultimately, having the right tools on hand protects valuable assets, safeguards personnel, and preserves the environment. Proactive spill preparedness is not just good practice; it is an essential part of responsible business operation.