Harbor Containment Booms: Essential Permanent Protection for Harbors & Ports

Harbors and ports are vital arteries of commerce and crucial marine ecosystems. Yet, they constantly face significant threats from pollution, including oil spills and floating debris. These issues jeopardize both environmental health and operational continuity. A harbor containment boom emerges as a proactive, indispensable solution. It is specifically engineered to provide robust, long-term marine protection against these pervasive threats. This post will delve into these critical marine pollution barrier systems. Readers will gain a deep understanding of their features, diverse applications, and significant benefits for modern port management.

A harbor containment boom is a specialized, durable floating harbor boom. It is designed as a physical barrier deployed on the surface of water bodies. You typically find these barriers within harbors, ports, and dock areas. Its primary function is to contain and control the spread of surface pollutants. This includes substances such as oil, chemicals, refuse, and general floating debris. By intercepting these contaminants, the boom prevents them from contaminating wider, more sensitive areas.

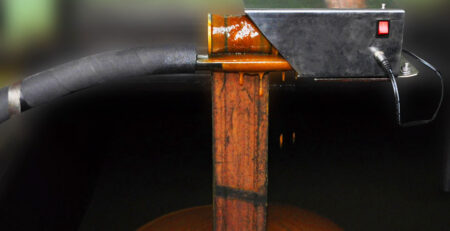

The basic structure of a harbor containment boom includes three key components. First, a flotation chamber keeps the boom buoyant on the water. Second, a freeboard is the part of the boom that extends above the water’s surface. This acts as a wall to stop pollutants from washing over. Third, a skirt extends below the water’s surface, preventing contaminants from flowing underneath. All these parts work together to sit effectively on the water’s surface, ensuring comprehensive interception and containment of pollutants.

The Critical Need for Harbor Protection: Why a Marine Pollution Barrier is Essential

Harbors are unique environments, making them particularly vulnerable to pollution. Specific factors contribute to this susceptibility. These include heavy vessel traffic, frequent fueling operations, and industrial activities. The confined nature of these areas can also greatly exacerbate the impact of spills. Without an effective marine pollution barrier, even small incidents can quickly escalate into major environmental and economic disasters.

The consequences of uncontained spills are severe. Environmentally, they cause harm to marine life, including fish, birds, and delicate habitats like coral reefs and mangroves. Economically, the impacts are substantial. These include costly cleanups, extensive operational downtime, and significant reputational damage to ports and businesses. Furthermore, regulatory penalties for environmental non-compliance can be hefty. This emphasizes the need for robust protective measures. Harbor containment booms serve as both a proactive preventative measure, such as creating permanent perimeters around fuel docks, and a reactive tool for rapid response to incidents. They act as a crucial marine pollution barrier in both scenarios.

Key Features and Advantages of a Permanent Oil Boom for Harbors

A permanent oil boom for harbors stands apart from temporary emergency response booms. These harbor containment boom systems are distinctively designed for long-term or semi-permanent deployment. This makes them ideal for continuous protection in busy waterways. Their construction focuses on enduring the constant demands of a marine environment.

Their durability stems from the robust materials used in construction. These often include heavy-duty PVC or urethane-coated fabrics. These materials offer exceptional resistance to UV degradation, chemical inertness, and abrasion. This resilience ensures the boom maintains its integrity even when exposed to harsh marine environments. Such booms are specifically designed for durability against constant exposure.

Furthermore, their design ensures superior stability and performance. They are engineered to withstand strong currents, waves, and tidal fluctuations commonly experienced in harbor settings. This prevents contaminants from washing over or under the boom, maintaining effective containment. Features that contribute to ease of inspection, maintenance, and cleaning also enhance their long-term operational efficiency. This thoughtful design ultimately reduces the total cost of ownership. Advanced mooring systems and robust interconnection methods, often using ASTM standard connectors, ensure secure, continuous, and reliable placement. This makes them a truly effective permanent oil boom solution.

Types and Applications of Oil Spill Boom for Harbors

The market offers various types of oil spill boom for harbors, each suited for different conditions and threats. These harbor containment boom configurations include:

- Solid Flotation Booms: These use cylindrical or box-shaped floats. They are known for their high buoyancy and stability, making them effective in diverse conditions.

- Fence Booms: Featuring flat panels with rigid internal supports, these booms create a strong, upright barrier. They are particularly good at containing debris and viscous oils.

- Air-Inflated Booms: These booms use air-filled chambers for flotation. They are often used for quick deployment and recovery, offering flexibility in response scenarios.

These booms have a wide array of specific deployment scenarios. They can be deployed around sensitive ecological habitats to shield them from potential spills. They are ideal for establishing permanent perimeters near fuel transfer points, creating a first line of defense. Isolating industrial discharge outlets or protecting marinas from pollution are also common uses. Ultimately, they can serve as a general protective barrier for entire harbor areas.

Selecting the right oil spill boom for harbors involves several key considerations. These include the boom height (freeboard) and skirt depth (draft), which determine how much of the boom sits above and below the water. The material type, strength requirements to withstand environmental forces, and the desired duration of deployment are also critical. These factors must align with the specific environmental conditions and anticipated threats of the harbor.

Benefits of Investing in High-Quality Harbor Containment Solutions

Investing in superior harbor containment boom technology brings multifaceted advantages. It signifies proactive environmental responsibility, significantly reducing ecological damage in the event of a spill. This commitment also ensures compliance with stringent marine environmental regulations, safeguarding ports from legal issues and fines.

Beyond environmental stewardship, there are substantial economic benefits. High-quality containment solutions lead to significant cost reduction by preventing or minimizing cleanup costs. They also mitigate fines and reduce operational downtime following a spill incident. It’s a clear example where prevention is far more cost-effective than remediation. Such systems also offer crucial protection of assets. This includes valuable marine ecosystems, vessels docked in the port, critical port infrastructure, and vulnerable shorelines from damage caused by oil and debris.

Finally, these solutions enhance safety and reputation. They improve safety for personnel and local communities by mitigating exposure to hazardous materials. This proactive stance also bolsters the port’s reputation as a responsible and environmentally conscious entity. It signals a commitment to sustainable operations and community well-being.

Conclusion: A Safer Future for Our Ports with Harbor Containment Booms

A thoughtfully chosen and properly deployed harbor containment boom is an indispensable asset. It serves as a cornerstone for safeguarding critical marine infrastructure and precious waterways. These systems fulfill a multifaceted role as a versatile, durable, and highly effective long-term solution against the persistent threats of oil spills and floating debris. This makes them an essential permanent oil boom and marine pollution barrier. Robust harbor containment solutions are not just an expense; they are an investment. An investment in ensuring a cleaner, safer, and more sustainable future for our ports and oceans.