Oil-Only Absorbents: Hydrophobic Spill Solution

Oil-Only Absorbents: The Hydrophobic Solution for Clean, Compliant Spill Response

Dealing with oil and hydrocarbon spills presents a significant challenge for businesses. These spills pose risks to ongoing operations, can harm the environment, create safety hazards for employees, and lead to hefty fines for non-compliance with regulations. Managing them effectively is crucial. This is where oil-only absorbents come in. Designed specifically for this task, they offer a targeted solution. Their unique ability to repel water while soaking up oil makes them highly efficient for spill response. Understanding what they are, how they work, and their various applications can help businesses achieve better cleanups and maintain compliance.

Simply put, oil-only absorbents are materials engineered to soak up oil and other hydrocarbons while actively pushing water away. They possess a fundamental characteristic known as hydrophobicity. Hydrophobic absorbents repel water. This property means they have a natural aversion to water molecules but a strong attraction to oil molecules (they are oleophilic). This dual nature is key to their effectiveness.

The reason this property is so important is that it allows them to work effectively in wet environments, or even directly on the surface of water. Unlike other absorbents that might soak up any liquid they encounter, oil-only absorbents remain dry when exposed to water, preserving their capacity solely for the oil or hydrocarbon spill. This selective absorption maximizes the amount of oil they can pick up before becoming saturated.

How Do Oil-Only Absorbents Work & Why Are They Different?

The mechanism behind oil-only absorbents relies on the specific materials they are made from. Often utilising synthetic polymers like polypropylene, their molecular structure is crafted to have a natural affinity for hydrocarbons. When these materials come into contact with a mix of oil and water, the oil molecules are attracted to and absorbed into the material’s fibres, while the water molecules are actively repelled and bead up on the surface.

This selective absorption is their primary differentiator. Consider universal absorbents, which soak up both oil and water. If you use a universal absorbent on an oil spill that is mixed with or on top of water, it will quickly become saturated with water, leaving less capacity for the oil. This not only reduces the amount of oil cleaned up but also significantly increases the volume of saturated waste material needing disposal.

The advantage of this difference is clear: efficiency. By absorbing only the oil or hydrocarbon, oil-only absorbents allow you to clean up more oil with less material. This leads to less waste generation, reduced disposal costs, and ensures the absorbent remains effective even when dealing with spills in rainy conditions or on water surfaces.

Key Applications and Use Cases for Oil-Only Absorbents

Due to their specific nature, oil-only absorbents are essential in numerous scenarios where oil or hydrocarbons must be removed, especially when water is present or likely to be involved.

Common applications include:

- Industrial Settings: They are crucial for handling leaks and drips around heavy machinery, storage tanks, pipelines, and manufacturing equipment. This includes spills involving lubricants, hydraulic fluids, cutting oils, and other petroleum-based products.

- Workshops and Garages: Routine cleanups of motor oil, transmission fluid, brake fluid, and other automotive fluids are simplified with oil-only pads and socks.

- Marine Environments: Their ability to float and repel water makes them invaluable for addressing oil spills on lakes, rivers, harbours, and marinas. They are also ideal for absorbing oil accumulation in boat bilges while leaving the water behind.

- Fuel Spill Management: As a dedicated fuel spill absorbent, they are vital at refueling stations, transport depots, and storage areas for cleaning up gasoline, diesel, kerosene, and jet fuel spills. For effective industrial spill cleanups, having the right type of absorbent readily available is critical.

- Any Situation: Use them wherever you need to remove hydrocarbons from a wet surface or a body of water without soaking up the water itself.

Benefits for Your Business Using Oil-Only Absorbents

Utilising oil-only absorbents for hydrocarbon spills provides several tangible advantages for businesses:

- Enhanced Efficiency: Because they only absorb the oil or hydrocarbon, less absorbent material is required to clean up a given volume of spill, particularly in wet conditions. This means you get more cleanup power from each pad, roll, or sock.

- Reduced Waste & Disposal Costs: Less saturated material results in less overall waste volume. This directly lowers disposal costs, which is particularly important as oil-saturated absorbents often require special, more expensive hazardous waste disposal.

- Environmental Protection: Quickly containing and cleaning up oil spills prevents them from spreading into surrounding soil or water bodies. This protects the environment, helps avoid costly remediation efforts, and demonstrates environmental responsibility.

- Improved Safety: Promptly containing and cleaning up oil spills eliminates slippery surfaces, reducing the risk of slips and falls. It also minimises the risk of fire, especially when dealing with flammable liquids like fuels.

- Regulatory Compliance: Having and using the appropriate spill response products, such as oil-only absorbents, helps businesses meet environmental regulations and avoid potential fines associated with improper spill handling.

- Cost-Effectiveness: While the initial cost per unit might sometimes differ from universal absorbents, choosing the correct absorbent for the job (oil-only for oil) is often more economical in the long run due to increased efficiency, reduced material usage, and lower disposal costs.

Types of Oil-Only Absorbents

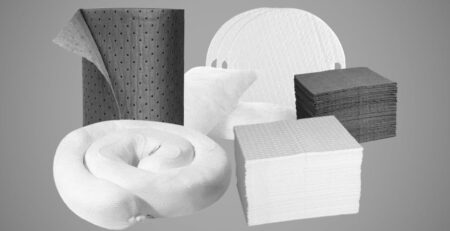

Oil-only absorbents come in various forms, each designed for specific types of spills and locations. Understanding these options helps you choose the best tools for your spill response plan.

Common types include:

- Pads: These are flat, absorbent sheets. They are excellent for wiping up small leaks and drips, lining surfaces under machinery to catch potential spills, or using manually to soak up contained spills.

- Rolls: Similar to pads but in a continuous roll format. They are useful for covering larger areas, lining walkways or large equipment bases, and can be cut to the specific size needed for a spill.

- Socks: Flexible, tube-like absorbents filled with absorbent material. They are designed to contain spills and prevent them from spreading, creating barriers around equipment, drains, or the edge of a spill.

- Booms: Larger diameter socks specifically engineered to float on water. They are used to contain spills on lakes, rivers, ponds, or harbours, preventing the oil from spreading further.

- Pillows: Bag-like absorbents filled with a large volume of absorbent material. They are ideal for absorbing larger volume leaks in confined spaces, catching drips from overhead pipes, or soaking up contained puddles.

These different types can often be used together as part of a comprehensive spill response strategy – for example, deploying booms to contain a spill on water, then using pads and pillows inside the contained area to soak up the oil.

Choosing the Right Oil-Only Absorbent

Selecting the appropriate oil-only absorbent for your needs is crucial for effective spill response. Considering a few key factors will help you make the best choice for managing hydrocarbons, including their use as a fuel spill absorbent.

Key factors to consider:

- Type of Hydrocarbon: While most oil-only absorbents work for a wide range of oils, fuels, and lubricants, confirming suitability for very specific or unusual liquids is always recommended.

- Size and Nature of the Spill: A small drip under a machine might only require a pad. A larger contained leak might benefit from a pillow. A spill that is spreading requires containment first, using socks on land or booms on water, before absorption begins with pads or pillows.

- Location of the Spill: Spills on hard surfaces on land are typically handled with pads, rolls, or socks. Spills on water or those near drains that could reach water necessitate floating booms for containment before absorption.

Matching the absorbent type to the specific spill situation ensures the most effective, efficient, and cost-effective cleanup of hydrocarbons.

Conclusion

In summary, oil-only absorbents are indispensable tools for effectively managing oil and hydrocarbon spills in various business settings. Their defining hydrophobic characteristic, which causes them to repel water while attracting oils and fuels, is their core advantage. This allows them to selectively absorb spills, even in wet conditions, maximising cleanup efficiency and minimising waste volume. Having the right types of oil-only absorbents readily available is not just about cleaning up messes; it’s a vital part of maintaining a safe workplace, protecting the environment, controlling costs, and ensuring regulatory compliance. Proactive spill preparedness, armed with the correct tools, is essential for any business that handles oils or hydrocarbons.