Understanding Oil Absorbents & Eco-Friendly Solutions

Oil spills, whether a minor drip in a workshop or a major industrial incident, are a significant problem. They pose threats to the environment, safety, and finances. Managing these spills effectively and quickly is critical. This is where oil absorbent materials become essential tools. This post will cover what oil absorbents are, why they are needed, the different types available, where they are used, and how to use them correctly. We will also highlight the increasing importance and benefits of choosing eco-friendly oil absorbent options for both your business and the planet.

What is an Oil Absorbent?

An oil absorbent is a material specifically designed to capture and hold oil and other liquids based on hydrocarbons, like fuels, lubricants, and solvents. These materials work by soaking up the oil through a process called absorption, where the liquid is drawn into the material’s structure, or adsorption, where the liquid sticks to the surface of the material.

Effective oil absorbents often have special properties. They are typically oleophilic, meaning they attract oils. Crucially, for spills involving water, they are also hydrophobic, meaning they repel water. This combination allows them to selectively soak up oil while leaving water behind. Oil absorbents come in various common forms, including flat pads and large rolls for covering areas, absorbent booms for containing spills on water, pillows for concentrated leaks, and granular materials for land-based spills.

Why Are Oil Spill Absorbents Necessary?

Leaving oil spills unaddressed can lead to severe consequences. These include extensive environmental damage, harming sensitive ecosystems, polluting water bodies and soil. They also create serious safety hazards, such as the risk of fire or slips and falls for workers. Furthermore, businesses can face costly regulatory fines, cleanup expenses, and potential legal liabilities.

Using oil spill absorbent products provides a rapid and effective way to respond to spills. They help contain the spill, preventing it from spreading further and minimizing its overall impact. By quickly applying these materials, you protect personnel, prevent damage to property, and safeguard the environment. Using the right absorbents is also key to helping businesses meet their compliance obligations related to spill prevention and cleanup.

The Evolution of Spill Cleanup

In the past, dealing with oil spills often involved using common materials like sand, clay, or sawdust. While these could soak up some liquid, they had significant limitations. They often had a low absorption capacity, were not selective (soaking up water along with oil), were not hydrophobic, and created large volumes of waste material to dispose of.

This led to the development of modern, engineered absorbent for oil spills. These materials are specially designed for much higher efficiency, better selectivity (primarily soaking up oil while repelling water), and are easier to handle and use. The focus has shifted towards using more sophisticated materials, driven by the need for better performance and a growing awareness of environmental concerns. This evolution includes exploring more sustainable and potentially biodegradable options.

Focus on Eco-Friendly and Biodegradable Solutions

An eco-friendly oil absorbent is typically made from materials that have a lower environmental impact. This often means they are derived from natural, renewable resources or use recycled materials. Their manufacturing process may also involve less energy or produce fewer pollutants. Many are designed to be non-toxic.

A biodegradable oil sorbent is a specific type of eco-friendly absorbent. These materials are usually made from organic sources, such as plant fibers, cotton, corn cob, or peat moss alternatives. Under the right conditions (like in a composting facility), the base material of a biodegradable oil sorbent can break down naturally over time. Choosing these types of absorbents offers core advantages, including reducing dependence on synthetic plastics, lowering the carbon footprint associated with production, and potentially reducing the persistence of the absorbent material itself in the environment after use (though the absorbed oil remains a separate disposal challenge).

Benefits of Using Eco-Friendly Absorbents

Using an eco-friendly oil absorbent offers multiple benefits beyond basic cleanup.

- Environmental Protection: They help minimize pollution. Biodegradable types can potentially reduce landfill volume associated with the absorbent material itself. Using sustainable options helps protect sensitive ecosystems during cleanup operations.

- Sustainability: Choosing absorbents made from renewable or recycled resources supports broader sustainable business practices and reduces the consumption of finite resources.

- Efficiency: Many modern eco-friendly absorbents are highly effective. They often provide absorption capacity and speed comparable to, or even exceeding, traditional synthetic products.

- Compliance: Utilizing environmentally responsible products aligns with increasing environmental regulations and can help businesses achieve corporate sustainability goals, improving their environmental profile.

- Reduced Liability: Demonstrating a commitment to using products with less environmental impact can enhance a company’s public image and potentially reduce long-term environmental cleanup liabilities.

It’s important to note the benefit of a biodegradable oil sorbent: while the sorbent material itself can break down, the oil it absorbs remains the primary concern and still requires proper, often specialized, disposal.

Applications: Where to Use Absorbent for Oil Spills

Knowing where to use absorbent for oil spills helps ensure preparedness.

On land, common scenarios include:

- Leaks and drips from machinery or vehicles in workshops and garages.

- Spills in manufacturing plants or industrial facilities.

- Handling areas for heavy equipment.

- Roadways and parking lots after accidents or leaks.

- Soil contamination sites requiring remediation.

For water-based spills, applications include:

- Lakes, rivers, ponds, and other freshwater bodies.

- Dock areas, ports, and marine environments.

The specific type of absorbent for oil spills you use should match the application. Granular or mat-type absorbents are best for land. For water, you need hydrophobic pads, rolls, or booms that float booms that float and selectively soak up oil without becoming saturated with water. Certain absorbents are more suited for land vs water.

Choosing the Right Oil Absorbent

Selecting the best oil absorbent requires considering several factors:

- Type of Liquid: Is it oil-only (hydrocarbons like oil and fuel)? Or is it a universal spill (which might include water-based liquids or chemicals)? Oil-only absorbents repel water. Universal absorbents soak up almost anything.

- Location: Is the spill on land or water? For water, hydrophobic, floating absorbents are essential.

- Spill Size/Rate: Small, ongoing drips might need a pad placed underneath. Larger spills require booms for containment and generous application of pads, rolls, or granular material.

- Volume Capacity: How much liquid can the absorbent hold per unit of material? Higher capacity means less material needed.

- Environmental Goals: If sustainability is a priority, choosing an eco-friendly oil absorbent or a biodegradable oil sorbent is a key consideration to align with your business’s environmental commitments.

How to Use Oil Spill Absorbents Effectively

Using oil spill absorbent correctly maximizes its effectiveness and ensures safety. Follow these steps:

- Assess the Situation: Quickly identify what spilled (oil, fuel, etc.), how large the spill is, and where it’s spreading.

- Ensure Safety: Always wear the appropriate Personal Protective Equipment (PPE), such as gloves, eye protection, and possibly respiratory protection, depending on the material spilled.

- Contain the Spill: Before applying absorbent, stop the spread. Use absorbent booms, socks, or other barriers to surround the spill area. Stop the source of the leak if possible.

- Apply Absorbent: Generously spread or lay the oil spill absorbent material over the contained spill area. Ensure complete coverage.

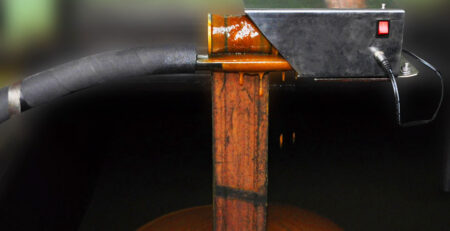

- Allow Absorption: Give the absorbent material time to soak up the oil. The time needed varies depending on the type of absorbent and the liquid. You’ll often see the material change color as it saturates.

- Collect Used Material: Once the absorbent is saturated, carefully collect it using brooms, shovels, or other appropriate tools. Avoid direct contact.

- Prepare for Disposal: Place the saturated, used absorbents into appropriate, labeled containers or bags specifically designed for hazardous waste.

Disposal of Used Absorbents

It is crucial to understand that used oil absorbent materials, once saturated with oil, are almost always classified as hazardous waste. This holds true even if the absorbent material itself is labelled as eco-friendly or biodegradable oil sorbent. The hazard comes from the absorbed oil, not the material itself.

Proper disposal is critical to prevent further environmental harm. You must strictly follow all local, state, and federal regulations regarding the collection, transportation, and disposal of hazardous waste. While a biodegradable oil sorbent base might break down eventually, the oil it holds requires specialized industrial processing or disposal methods to ensure it does not re-contaminate the environment. It is highly recommended to consult with qualified waste disposal experts to ensure compliance and safe handling.

Conclusion

Oil absorbent materials are indispensable tools for effective and responsible spill management. They are vital for quickly containing and cleaning up hazardous hydrocarbon spills, protecting people, property, and the environment from damage. Choosing the right absorbent based on the spill type and location is key. Increasingly, opting for an eco-friendly oil absorbent solution is not just a preference but a crucial step towards greater sustainability and compliance. By understanding and properly using these materials, especially environmentally conscious options, businesses can significantly improve their spill response while contributing to a healthier planet.