Polypropylene Absorbents: Oil Spill Cleanup Guide

Oil spills pose a severe threat, impacting businesses financially, damaging the environment, and compromising operational safety. Effective containment and rapid cleanup are not just important; they are absolutely critical. In this urgent landscape, polypropylene absorbents stand out as the industry’s leading solution for tackling oil-based spills. Engineered with unique oleophilic (oil-attracting) and hydrophobic (water-repelling) properties, these materials offer an unparalleled advantage. This article will explore what oil polypropylene absorbents are, highlight their many advantages, delve into different types like meltblown absorbents and nonwoven absorbents, compare them to other materials, and discuss their practical applications. This knowledge will empower you to make informed choices for robust spill preparedness.

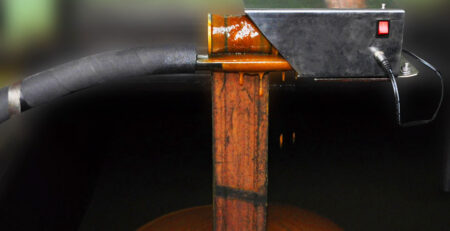

polypropylene absorbents are specialized synthetic fiber absorbents crafted specifically from polypropylene polymer. Their unique design allows them to selectively absorb hydrocarbons, such as oils, fuels, and lubricants, while effectively repelling water. This dual functionality is key to their superior performance.

Key Properties – Oleophilic and Hydrophobic

The effectiveness of polypropylene lies in its distinct molecular structure, which grants it two crucial properties:

- Oleophilic (Oil-Attracting): Polypropylene’s chemical makeup creates a strong natural affinity for oil. This means that when it comes into contact with hydrocarbons, its fibers quickly draw in and encapsulate the oil. This magnetic-like attraction ensures rapid and thorough absorption.

- Hydrophobic (Water-Repelling): At the same time, polypropylene naturally repels water. This property is vital, especially in wet environments or when dealing with spills on water. It ensures that the absorbent material does not become saturated with water, maintaining its capacity to absorb only the oil. This makes oil polypropylene absorbents highly efficient and economical, as less material is needed for a given spill volume.

The Unmatched Advantages of Polypropylene in Oil Spill Response

The distinct characteristics of polypropylene absorbents offer significant advantages in various spill scenarios, making them the preferred choice for many businesses.

- High Absorption Capacity: Polypropylene can absorb a remarkable amount of oil relative to its own weight, often between 10 to 25 times. This exceptional capacity means that less absorbent material is required to clean up a spill, which in turn leads to reduced material costs and significantly lower disposal expenses.

- Efficiency and Speed: Their rapid wicking action allows polypropylene absorbents to quickly contain and clean up spills. This speed is crucial for minimizing the spread of contaminants, significantly reducing environmental impact, and limiting costly downtime for businesses.

- Versatility in Forms: These absorbents are available in a wide array of forms to suit diverse spill scenarios. Pads are ideal for small drips and leaks, while rolls are perfect for covering larger areas or creating absorbent walkways. Booms are specifically designed for containing spills on water, preventing their spread, and pillows are excellent for absorbing larger volumes in tight or hard-to-reach spaces like sumps or around machinery.

- Durability and Reusability (for some types): Many polypropylene absorbents are engineered for robust performance, resisting tearing and fraying even when saturated. Furthermore, certain types can be wrung out after use to recover absorbed liquids, allowing for the potential reuse of the material. This contributes to cost-effectiveness and reduces waste.

Exploring Types of Polypropylene Absorbents

While all polypropylene absorbents share the core oleophilic and hydrophobic properties, their manufacturing processes result in different structures and ideal applications. The two main categories often discussed are meltblown and nonwoven types.

Meltblown Absorbents

Meltblown absorbents are a specialized form of oil polypropylene absorbents known for their exceptional performance.

- Description: The meltblown manufacturing process involves extruding molten polypropylene through incredibly fine dies. High-velocity air then blows these molten fibers, creating an intricate web of extremely fine, randomly entangled fibers. This process results in a dense material with a vast internal surface area and high pore volume.

- Benefits: The fine fiber structure and high pore volume give meltblown absorbents outstanding absorption speed and capacity. They are highly effective for general purpose spills and are particularly adept at handling high-viscosity oil spills, quickly encapsulating even thick hydrocarbons.

- Common forms: Meltblown absorbents are primarily found as pads and rolls, making them ideal for wiping surfaces, soaking up spills, and covering extensive areas.

Nonwoven Absorbents (Broader Category)

The term nonwoven absorbents is a broader classification that encompasses various manufacturing techniques beyond just meltblown.

- Explanation: Nonwoven materials are those where fibers are bonded together through mechanical, thermal, or chemical means, without the traditional weaving or knitting processes. This category includes meltblown, but also spunbond, needle-punched, and thermal-bonded methods, each yielding different material properties.

- Structural Variation and Application: The diverse manufacturing techniques lead to a variety of nonwoven structures. For instance, dimpled, perforated, or laminated polypropylene absorbents can offer varying levels of strength, density, and durability. These structural differences enable specific applications. For more detailed insights into the applications of melt-blown and other nonwoven types, further research highlights their diverse uses in many fields.

- Differentiation: It is important to differentiate between meltblown absorbents, which are celebrated for their superior absorbency and speed due to their fine fiber structure, and other nonwoven absorbents. While meltblown excels at rapid spill absorption, other nonwoven types might offer enhanced tensile strength, tear resistance, or specific filtration properties, making them better suited for heavy-duty wiping, containment, or other specialized spill scenarios requiring more robust materials.

Polypropylene Absorbents vs. Other Materials

When it comes to spill cleanup, polypropylene absorbents consistently outperform other options, both synthetic and natural.

Comparison to Other Synthetic Fiber Absorbents

While other synthetic fiber absorbents like polyester blends exist, polypropylene generally offers a superior balance. Polypropylene’s inherent oleophilic and hydrophobic properties are more pronounced, leading to a typically higher absorption rate and capacity specifically for oil. This means more oil is captured per unit of absorbent, making cleanup more efficient.

Comparison to Natural Absorbents

Polypropylene absorbents are overwhelmingly preferred over traditional natural absorbents such as clay, sawdust, corn cob, or peat moss. The reasons are compelling:

- Higher Absorbency-to-Weight Ratio: Polypropylene absorbs significantly more oil relative to its weight, meaning less material is needed and fewer full bags to dispose of.

- Less Bulk for Disposal: Because they absorb more and don’t soak up water, polypropylene absorbents result in far less saturated waste volume, leading to lower disposal costs.

- Non-Absorption of Water: Unlike natural absorbents that can become saturated with water and lose their ability to absorb oil, polypropylene remains effective in wet conditions.

- Minimal Dust or Residue: Natural absorbents often leave behind dusty residue, requiring additional cleanup. Polypropylene absorbents are clean and leave virtually no residue.

Choosing the Right Polypropylene Absorbent for Your Specific Needs

Selecting the appropriate polypropylene absorbents is key to effective spill response. Several factors should guide your decision.

Factors to Consider

- Spill Volume and Type: Estimate the quantity of oil or other hydrocarbons involved. Also, identify the type of oil (e.g., light fuel, heavy crude, or a specific chemical). This determines the necessary absorbency and ensures chemical compatibility.

- Environmental Conditions: Consider where the spill occurs. Is it on land (e.g., concrete, soil) or water (calm or rough)? Is it indoors or outdoors? These conditions will dictate the most suitable product form and weight.

- Regulatory Compliance: Be aware of any industry-specific regulations or environmental guidelines that might influence your choice of absorbent. Compliance is crucial for responsible operations.

Matching Product Form to Application

The versatility of polypropylene absorbents means there’s a perfect form for almost any situation:

- Pads: Ideal for addressing small drips, leaks, and for general wiping of contaminated surfaces.

- Rolls: Best suited for covering large floor areas, creating absorbent walkways, or for continuous absorption beneath leaky machinery.

- Booms are specifically designed for containing and absorbing spills on water, preventing their spread and concentrating the oil for easier recovery.

- Pillows/Socks: Excellent for absorbing larger volumes in confined or tight spaces, sumps, or positioned directly around the base of machinery to catch leaks.

Common Applications of Oil Polypropylene Absorbents

The widespread utility of oil polypropylene absorbents makes them indispensable across numerous sectors that handle hydrocarbons.

- Industrial Facilities: Factories, manufacturing plants, workshops, and machine shops rely on these absorbents for daily maintenance, preventing slips, and managing inevitable spills of hydraulic fluid, cutting oils, or lubricants.

- Marine Environments: Their critical role extends to marinas, ports, shipyards, and offshore drilling operations. They are vital for handling fuel spills, bilge leaks, and general dockside incidents, protecting aquatic ecosystems.

- Automotive Sector: Garages, vehicle maintenance bays, auto body shops, and gas stations routinely use oil polypropylene absorbents for oil changes, fluid leaks from vehicles, and general shop cleanup.

- Emergency Preparedness and Hazmat Response: A fundamental component of any robust spill kit, they are designed for rapid deployment during unforeseen emergencies across various sectors. This includes quick response to hydrocarbon spills and, when chemically compatible, even certain chemical spills, supporting environmental remediation efforts.

Conclusion

Polypropylene absorbents are undeniably the premier solution for efficient and responsible oil spill management. Their critical role and unmatched effectiveness stem from their unique ability to absorb oil rapidly while repelling water. Businesses dealing with hydrocarbons benefit immensely from including these absorbents as a key component of their modern safety protocols and responsible environmental practices. Choosing the right oil polypropylene absorbents ensures optimal spill preparedness, enhances worker safety, and provides crucial environmental protection.