Debris Boom: The Essential Solution for Waterway Debris Containment

Our world’s aquatic environments face a growing challenge from floating debris and pollutants. From natural matter like logs and leaves to pervasive man-made waste and insidious microplastics, these contaminants impact rivers, canals, reservoirs, and industrial waterways globally. Such debris poses a significant threat to delicate ecosystems, marine and riparian wildlife, and vital infrastructure. Fortunately, a proactive and robust solution exists: the debris boom. This essential waterway debris containment boom is engineered to mitigate these critical issues effectively.

This post will define these crucial floating debris barriers, explore their diverse applications across various industries, and detail the significant commercial and environmental benefits they offer.

What is a Debris Boom? Defining the Floating Barrier

A debris boom is a specialized floating debris barrier specifically engineered to intercept, contain, and divert various types of floating materials on the surface of water bodies. Its primary function is to act as a physical barrier, preventing the uncontrolled spread of everything from natural refuse like logs, branches, and leaves, to man-made litter, and even hazardous industrial discharge.

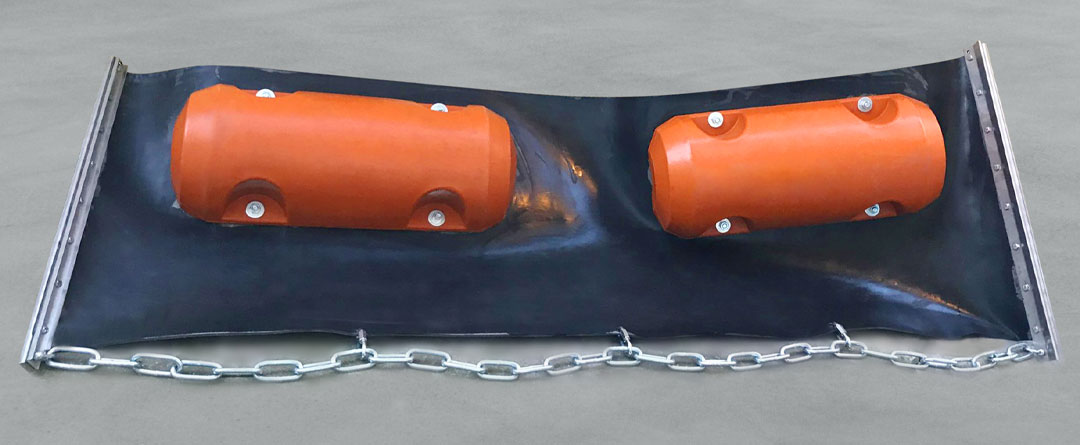

A standard debris boom comprises fundamental components working in unison. Buoyant floatation chambers provide essential surface support, ensuring the barrier stays afloat. Below the surface, a subsurface skirt or barrier panel is designed to effectively capture submerged debris. Robust connectors link individual sections together, creating a continuous, effective barrier. These components integrate seamlessly to form a highly efficient floating litter boom, guiding debris towards designated collection points or safely away from sensitive areas.

Why Debris Containment is Critical: Protecting Environments and Operations

Floating debris originates from various common sources, including stormwater runoff, industrial effluent, recreational litter, and natural events like floods. These contribute to the persistent challenge of waterway debris containment. The types of debris encountered are diverse: organic matter such as logs, branches, and leaves; man-made refuse like plastics, packaging, and tires; hazardous materials; and even oil sheens. This variety underscores the critical need for a versatile floating debris barrier solution.

The environmental impacts of uncontrolled debris are severe. They include habitat destruction, entanglement and ingestion hazards for wildlife, degradation of water quality, and disruption of aquatic ecosystems. Beyond ecological harm, there are significant operational and commercial consequences:

- Clogging of Water Intakes: Debris can obstruct water intakes for power generation, municipal water treatment, and industrial cooling systems. This leads to costly downtime, reduced efficiency, and potential equipment failure.

- Damage to Infrastructure: Vessels, maritime infrastructure, and shoreline properties are vulnerable to damage from floating debris, incurring significant repair expenses.

- Non-Compliance with Regulations: Accumulation and spread of debris can lead to non-compliance with environmental regulations and discharge permits. This results in potential fines, legal action, and reputational damage for businesses and municipalities.

- High Cleanup Costs: Manual cleanup operations are often inefficient, hazardous for personnel, and fail to address the root cause of debris spread, leading to continuously high costs.

Applications Across Industries: Where a Waterway Debris Containment Boom Excels

A waterway debris containment boom provides invaluable protection and operational support across a broad spectrum of environments. These highly adaptable barriers ensure cleaner, safer, and more efficient water management.

- Hydropower & Water Treatment Facilities: Debris booms prevent logs, weeds, and trash from clogging crucial water intakes and turbines. This ensures uninterrupted power generation and efficient water purification processes.

- Marinas & Recreational Areas: Deploying a floating litter boom keeps harbors, beaches, and swimming areas clear of floating litter and natural debris. This significantly enhances visitor experience, improves safety, and maintains aesthetic appeal.

- Construction & Dredging Sites: These booms are vital for containing construction-related debris, sediment, and pollutants within designated areas. This prevents environmental spread and aids in achieving regulatory compliance.

- Industrial Facilities: Industrial operations utilize these booms to manage discharge points effectively, containing effluent and preventing the escape of industrial waste. This protects nearby water bodies from contamination.

- Public Waterways (Rivers, Canals, Lakes): Strategically deployed debris booms intercept and divert accumulating trash and natural debris. This maintains navigable channels, preserves ecological health, and supports local wildlife.

- Reservoirs & Irrigation Systems: Protecting vital water sources, these booms prevent contamination by floating vegetation, plastics, and other unwanted materials that can impede flow or degrade water quality.

- Flood Management & Stormwater Outfalls: Acting as a floating litter boom, they capture significant volumes of debris carried by heavy rainfall and floodwaters. This prevents downstream damage, blockages, and costly infrastructure repairs.

- Temporary Spill Response: Booms can be rapidly deployed to contain accidental spills of non-hazardous materials or larger floating debris following an environmental incident, minimizing spread.

Tackling the Global Crisis: The Debris Boom as a Plastic Pollution Barrier

The pervasive and growing crisis of plastic pollution in global waterways presents long-term environmental and ecological consequences, including the formation of harmful microplastics. In response, debris booms are increasingly vital as a specialized plastic pollution barrier. These booms are strategically deployed to capture plastic waste — bottles, bags, and even microplastics — at critical junctures within rivers, canals, and coastal areas.

The widespread problem of global plastic pollution in aquatic environments highlights the urgent need for effective interception strategies. These floating debris barriers act as interceptors, preventing plastics from flowing further downstream into larger bodies of water or the open ocean, where removal becomes exponentially more difficult.

Booms optimized for plastic collection often feature specific design considerations:

- Finer Mesh or Solid Skirt Materials: These are crucial for capturing smaller plastic particles and microplastics more effectively than standard debris skirts.

- Robust Construction: The boom must withstand continuous accumulation of plastics and potential high flow rates without failure.

- Integrated Collection Systems: Systems for efficient removal of captured plastics are often integrated, minimizing manual effort and maximizing collection efficiency.

- Durability and UV Resistance: Long-term deployment in challenging conditions where plastic accumulation is constant requires exceptional durability and resistance to UV degradation.

Key Features and Types of High-Performance Debris Booms

A diverse range of debris booms is available, designed to meet specific operational and environmental demands. Understanding these types and features is crucial for effective waterway debris containment.

Types of Debris Booms:

- Permanent Booms: Designed for long-term, continuous deployment in high-debris areas, these often feature heavy-duty construction and robust anchoring systems for maximum stability and longevity.

- Temporary/Deployable Booms: Lightweight and easily deployable, these are ideal for short-term projects, emergency response, or seasonal use, offering flexibility and quick setup.

- Heavy-Duty vs. Light-Duty: Differentiated by material strength and floatation capacity, these booms are selected based on the anticipated debris loads, current speeds, and potential impact forces.

- Solid Float Booms: Featuring continuous, hard-shell floats, these provide excellent buoyancy, high impact resistance, and superior durability, particularly in rough or high-current conditions.

- Self-Inflating/Inflatable Booms: These booms offer compact storage and rapid deployment, making them highly suitable for quick response scenarios where time is a critical factor.

Essential Features for a High-Performance Floating Debris Barrier:

- Robust & Durable Materials: Look for UV-resistant, abrasion-resistant, and chemical-resistant fabrics (e.g., PVC, urethane) to ensure longevity in harsh aquatic environments.

- Effective Floatation & Skirt Depth: Adequate buoyancy is essential to keep the boom afloat in choppy conditions, while a sufficient skirt depth captures a wide range of floating and slightly submerged debris.

- Modular Design & Connectors: A modular design allows for customization of boom length, easy section replacement, and secure linking of multiple sections for adaptability to various site configurations.

- Strong Anchoring & Mooring Systems: These are crucial for maintaining the boom’s position against strong currents, wind, and debris loads, preventing drift and ensuring consistent performance.

- Ease of Deployment, Retrieval & Storage: User-friendly design minimizes labor, reduces the need for specialized equipment, and simplifies operational complexity.

- Low Maintenance Requirements: Materials and design should reduce the need for frequent cleaning and repairs, thereby minimizing operational costs over the lifespan of the boom.

The importance of customization options cannot be overstated. Matching specific site conditions, water flow rates, and the predominant types of debris targeted ensures efficient waterway debris containment and optimal system performance.

The Commercial Advantages: Benefits of Investing in a Debris Boom Solution

Investing in a debris boom solution offers compelling commercial advantages for businesses and municipalities alike, proving to be a strategic decision rather than just an expense. A high-quality floating debris barrier delivers both immediate and long-term returns.

- Enhanced Operational Efficiency:

- Prevents debris accumulation from clogging critical water intakes, pumps, and cooling systems. This minimizes equipment damage and costly, unscheduled downtime.

- Ensures smooth and uninterrupted operations for facilities that rely on clean water, such as power plants, manufacturing plants, and municipal water treatment facilities.

- Significant Cost Savings:

- Avoids expensive emergency cleanup operations and manual debris removal, which are often labor-intensive, hazardous, and unsustainable in the long run.

- Reduces repair and replacement costs for damaged infrastructure, vessels, and machinery that would otherwise be impacted by uncontrolled floating debris.

- Mitigates financial penalties and legal liabilities associated with environmental non-compliance and pollution incidents, protecting against unforeseen expenses.

- Demonstrated Environmental Responsibility:

- Showcases a proactive and tangible commitment to environmental stewardship and sustainability, actively protecting local ecosystems and wildlife.

- Enhances corporate image and public relations, fostering trust with stakeholders and communities by visibly addressing pollution concerns.

- Ensured Regulatory Compliance:

- Helps meet stringent environmental regulations, discharge permits, and local ordinances pertaining to waterway cleanliness and pollution prevention.

- Proactively addresses potential violations before they occur, avoiding legal complications, fines, and reputational damage.

- Improved Safety and Risk Reduction:

- Reduces hazards for personnel working near water bodies by containing potentially dangerous floating objects and preventing their uncontrolled movement.

- Protects public safety in recreational areas by keeping waterways clear of harmful litter and debris, acting as a reliable floating litter boom.

Choosing the Right Debris Boom for Your Specific Needs

Selecting the optimal debris boom solution requires careful consideration. A tailored approach is critical for truly effective waterway debris containment.

Assess Waterway Conditions:

- Current Speed & Flow Dynamics: Different boom designs are suited for slow-moving rivers versus high-current areas, influencing anchoring requirements and overall boom strength.

- Water Depth & Fluctuations: Consider the required skirt depth and whether the boom needs to adapt to changing water levels, such as in tidal zones, reservoirs, or flood-prone areas.

- Wave Action & Wind Exposure: The robustness of floats and connectors must withstand environmental forces to prevent dislodgement or damage, ensuring continuous performance.

Analyze Debris Characteristics:

- Type of Debris: Determine if the debris is primarily natural (logs, vegetation), man-made (plastics, litter), or industrial, as this influences the ideal skirt material and mesh size for a suitable plastic pollution barrier or heavy-duty option.

- Volume & Accumulation Rate: This dictates the required strength, buoyancy, and potential need for integrated collection systems for efficient debris removal.

Consider Deployment & Durability:

- Deployment Duration: Permanent installations demand highly durable materials and robust anchoring, while temporary needs favor ease of deployment and retrieval.

- Maintenance & Accessibility: Evaluate how often the boom will be cleared and if the site is easily accessible for maintenance and debris removal operations.

Budgetary Constraints:

- Balance the initial investment with long-term durability, anticipated maintenance costs, and the significant cost savings achieved through effective debris prevention.

Specific Site Requirements & Regulations:

- Account for any unique local environmental regulations, logistical challenges, or operational constraints that might necessitate custom solutions.

Emphasize the importance of expert consultation. Engaging with experienced suppliers or engineers is crucial to conduct a professional site assessment and recommend a customized floating debris barrier system that maximizes efficiency and longevity for your specific needs.

Conclusion: Safeguarding Waterways with Smart Debris Management

Debris booms play a profound and indispensable role as a cornerstone of modern waterway management and environmental protection. They offer dual value, acting as an effective, practical waterway debris containment boom that safeguards critical infrastructure and ensures operational continuity. Simultaneously, they serve as a crucial tool in the global fight against various pollutants, notably as a vital plastic pollution barrier.

Investing in a high-quality floating debris barrier is not merely an expense, but a strategic investment in environmental stewardship, operational resilience, and significant long-term cost savings. We encourage businesses, municipalities, and facility managers to assess their unique waterway challenges and explore tailored debris boom solutions to secure cleaner, safer, and more efficient aquatic environments for the future.