Debris Boom: Guide to Floating Barriers & Water Debris

Debris Boom: Your Ultimate Guide to Floating Debris Barriers & Water Debris Containment

Floating debris is a pervasive and escalating problem in our waterways. From plastics and discarded items to logs, vegetation, and general trash, rivers, lakes, reservoirs, and coastal areas or ports constantly battle unwanted materials. This debris causes significant harm, impacting environmental health, hindering operational efficiency, and posing serious safety risks. Recognizing and addressing this challenge is vital for maintaining clean and functional aquatic environments.

Enter the debris boom. This specialized floating barrier system is specifically designed to intercept, block, collect, or redirect unwanted floating materials. These robust floating debris barriers are essential tools, providing a proactive and effective solution for managing floating materials before they cause damage or pollution. Understanding effective water debris containment is crucial across diverse environments. This guide will cover both foundational knowledge and practical considerations for commercial applications, ensuring you can make informed decisions.

Understanding the Floating Debris Challenge

The uncontrolled spread of floating debris leads to numerous negative impacts. Environmentally, it causes habitat destruction, pollutes water bodies, and leads to aquatic life entanglement. Operationally, it results in severe disruptions, clogging water intakes, damaging boat propellers, and hindering safe navigation for vessels. Furthermore, it creates significant safety hazards for marine infrastructure, recreational users, and human activity in general.

These persistent problems highlight the critical need for proactive water debris containment strategies. Preventing the spread and accumulation of debris at its source is far more efficient and significantly less costly than undertaking extensive post-incident cleanup operations. Investing in preventative measures safeguards assets and the environment.

What Exactly is a Debris Boom?

A debris boom is a physical barrier engineered to control the movement of floating objects on water. Its core function is to contain, collect, or divert debris, preventing it from reaching sensitive areas or spreading further downstream. These booms are not merely passive floating lines; they are carefully constructed systems designed for resilience and effectiveness.

A typical floating debris barrier comprises several key components working in unison. Resilient floats provide the necessary buoyancy to keep the barrier afloat. A robust skirt extends below the water surface, acting as the primary mechanism to capture or deflect debris. A strong tension member, often a cable or chain running along the boom, provides structural integrity and allows the system to withstand the forces of currents and collected debris. Ballast weights ensure the skirt remains vertical and properly deployed underwater, preventing debris from escaping underneath. Finally, durable connectors link individual boom sections, creating a modular system that can extend across vast distances or be arranged in specific configurations. These components collectively enable the boom to manage, contain, or redirect floating materials efficiently. To fully understand boom components and their function, you can read more about their design and structural elements.

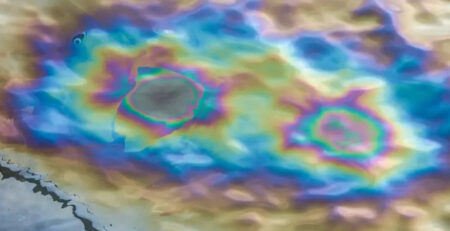

It is important to distinguish debris booms from other types of floating barriers, such as oil containment booms. While both float, oil booms are specifically designed to contain liquid hydrocarbons that sit on the water’s surface. Debris booms, however, are purpose-built to manage solid floating waste, from small plastics to large logs and vegetation, requiring different design characteristics and material strengths.

Types of Floating Debris Barriers: Finding the Right Fit

When selecting a floating boom for debris, understanding the different types available is crucial. These barriers vary significantly in design and application, tailored to specific environmental conditions and debris challenges.

One primary distinction lies between permanent and temporary/deployable systems. Solid Flotation Booms are examples of durable, permanent installations, robustly anchored for long-term protection of critical infrastructure or continuous debris interception in high-flow areas. Conversely, temporary options are lightweight and rapidly deployable, ideal for emergency response, short-term projects, or transient debris events.

The construction materials of floating debris barriers are also diverse, each offering unique properties. High-density polyethylene (HDPE) is frequently used for rigid boom sections, providing exceptional durability and resistance to impacts. PVC (polyvinyl chloride) materials offer flexibility, excellent chemical resistance, and are often used for booms that need to conform to complex shorelines. Reinforced fabrics, such as those made from robust polyester or nylon, offer high tensile strength while maintaining a lighter weight, suitable for deployable or less extreme applications. Material choice directly impacts the boom’s resistance to UV degradation, abrasion, and various environmental conditions, affecting its lifespan and effectiveness.

Variations in skirt depth and floatation size are also critical design elements. Skirt depth is optimized based on the type of debris being targeted – a deeper skirt is needed for semi-submerged objects like logs, while shallower skirts suffice for surface trash. Floatation size dictates the boom’s buoyancy and stability, with larger floats and more robust designs necessary for water bodies with strong currents or significant wave action.

For the most challenging environments, specialized marine debris boom designs are engineered with enhanced strength, superior UV protection, and robust anchoring systems. These are built to withstand the rigorous demands of strong currents, tidal zones, and exposed coastal areas, providing reliable containment in open water conditions.

Key Applications of Debris Booms

Debris boom systems are indispensable tools deployed across a wide range of environments, playing a critical role in safeguarding infrastructure, promoting environmental health, and ensuring operational continuity.

In rivers and canals, booms protect critical infrastructure such as bridges, dams, hydropower intakes, and culverts from damage caused by logs, excessive vegetation, and general urban trash. They prevent blockages that can disrupt water flow and lead to structural damage.

Lakes and reservoirs benefit greatly from these barriers by helping maintain water quality, safeguarding recreational areas like swimming zones and marinas from floating hazards, and protecting vital water supply intakes from clogging.

Within ports, marinas, and harbors, marine debris boom applications are crucial for ensuring navigation safety, protecting docked vessels from impact, preventing debris from damaging propellers, and safeguarding sensitive marine infrastructure. They keep busy waterways clear and functional.

At industrial and construction sites, debris booms are deployed to contain runoff, preventing construction debris, sediment, and other materials from entering natural waterways. They also block external debris from entering a site’s water-facing areas.

Finally, hydroelectric facilities rely heavily on debris booms. These systems are critical for preventing large logs and excessive vegetation from reaching and damaging expensive turbines, thereby ensuring continuous power generation and avoiding costly shutdowns.

The Benefits of Effective Water Debris Containment

Investing in robust water debris containment solutions offers a multitude of significant advantages, spanning environmental, operational, safety, and financial aspects.

From an environmental protection standpoint, these systems drastically reduce pollution in waterways, safeguard delicate aquatic ecosystems, and improve overall water quality. They are also vital in mitigating the spread of microplastics, which pose a long-term threat to marine life and human health.

In terms of operational efficiency, effective debris containment prevents costly equipment damage, significantly reduces downtime typically required for manual cleanup operations, and ensures an uninterrupted flow for critical water intakes and safe navigation pathways. This leads to smoother operations and reduced logistical burdens.

Enhanced safety is another paramount benefit. Debris booms create safer waterways for recreational activities like boating and swimming by eliminating collision hazards. They also protect vessels from potential propeller damage and reduce risks for maintenance personnel who would otherwise be exposed to dangerous debris removal tasks.

Finally, the cost savings achieved through effective debris containment are substantial. By preventing debris-related issues, businesses and municipalities can lower long-term expenses associated with manual debris removal, costly equipment repair or replacement, and extensive environmental remediation efforts, making them a wise long-term investment.

Choosing the Right Floating Debris Barrier for Your Needs

Selecting the optimal floating debris barrier is a critical decision that depends heavily on the specific challenges of your waterway. Careful consideration of several factors will ensure you acquire the most effective floating boom for debris for your application.

- First, assess the type and volume of debris you expect to encounter. Is it primarily logs and large vegetation, or smaller items like plastics and general trash? Understanding the characteristics (size, density, buoyancy) and the typical quantity of debris will guide the required boom strength and skirt depth.

- Second, thoroughly evaluate the water conditions. This includes current speed, potential wave action, water depth, tidal fluctuations, wind exposure, and the possibility of ice formation. These environmental forces dictate the necessary buoyancy, anchoring system, and overall robustness of the barrier.

- Durability and material choice are paramount for longevity. Consider how long the barrier needs to perform and its resistance to UV radiation, chemicals present in the water, and abrasion from debris or natural elements. The overall environmental stress on the boom will influence the most suitable construction materials.

- The ease of installation, deployment, and retrieval is also a practical consideration. Assess the logistics involved, the equipment required, and the personnel needed for setting up and removing the floating boom for debris. For temporary solutions, rapid deployment is key.

- Maintenance requirements and longevity should be factored into your decision. Understand the routine inspection, cleaning, and repair needs to ensure the maximum lifespan and continued effectiveness of the boom. Proactive maintenance extends the system’s useful life.

- Finally, consider your budget and overall cost-effectiveness. While initial investment is important, balance it with the long-term performance of the barrier, ongoing maintenance costs, and the significant potential savings from preventing debris-related damage and cleanup expenses. Choosing a cheaper, less effective solution may lead to higher costs down the line.

Installation & Maintenance Best Practices for Your Debris Boom

Proper installation and diligent maintenance are key to maximizing the effectiveness and lifespan of your debris boom system, ensuring reliable water debris containment.

- Before installation, conduct a thorough site assessment and planning. This involves surveying water currents, depth variations, and identifying suitable, stable anchoring points along the shoreline or within the water body. A well-planned layout will optimize the boom’s performance.

- When installing, focus on proper anchoring techniques. Depending on the environment, this could involve deadweight anchors, helical anchors, or shore anchors. Ensure appropriate tensioning is applied to the boom lines, and that connection points between boom sections are secure and robust. This creates a stable and resilient debris boom system capable of withstanding environmental forces.

- Regular inspection is vital. Routinely check the boom for any signs of structural damage, wear and tear on components, and especially for excessive debris accumulation. Early detection of issues allows for timely intervention.

- Implement clear cleaning protocols. Advise on efficient methods for removing collected debris. This could involve using specialized equipment or manual processes. Regular cleaning is crucial to maintain the boom’s effectiveness and prevent it from becoming overwhelmed, leading to overflow or sinking.

- Be prepared for necessary repairs. Guide on patching damaged boom sections, replacing worn or broken components like floats or connectors, and engaging in proactive maintenance to extend the system’s lifespan. Small repairs can prevent larger, more costly issues.

- Finally, consider storage considerations for off-seasons or periods of non-use. Proper cleaning, thorough drying, and secure storage in a sheltered area will prevent material degradation, extending the boom’s readiness and overall service life.

Conclusion

Debris boom solutions play a vital and indispensable role in protecting our waterways, critical infrastructure, and overall environmental health. These specialized floating debris barrier systems offer a proactive, efficient, and sustainable approach to managing unwanted materials in aquatic environments.

The value of carefully choosing the appropriate floating debris barrier cannot be overstated. By considering the specific environmental challenges and operational needs of your site, you can select a solution that provides optimal performance and longevity. Businesses, municipalities, industrial facilities, and environmental organizations are encouraged to consider these robust solutions for sustainable, efficient, and cost-effective water debris containment.