Oil Absorbent Booms: Your First Line of Defense Against Spills

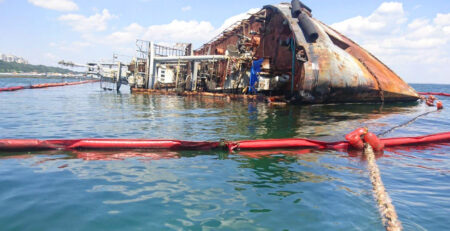

Oil spills pose significant environmental and financial risks to businesses of all sizes. Whether a small leak from machinery or a larger incident, effectively managing spills is critical. A fundamental tool in effective oil spill cleanup is the oil absorbent boom. These essential items are designed to contain and absorb oil spills, preventing them from spreading and causing further damage. This post will delve into what oil absorbent booms are, how they work, their different types, and why they are vital for quick and effective spill response. Understanding their critical role helps businesses mitigate damage, protect the environment, and ensure compliance with regulations.

What is an Oil Absorbent Boom?

An oil absorbent boom is a flexible barrier specifically designed to manage liquid spills, particularly hydrocarbons like oil. It serves a dual purpose in spill management:

- Containment: The boom acts as a physical barrier. On water, it floats to create a visible and physical perimeter, stopping the spread of oil across the surface. On land, it can be placed to surround a spill area or divert flow away from sensitive areas like drains.

- Absorption: The boom contains absorbent materials within its structure. These materials soak up the spilled oil, removing it from the environment.

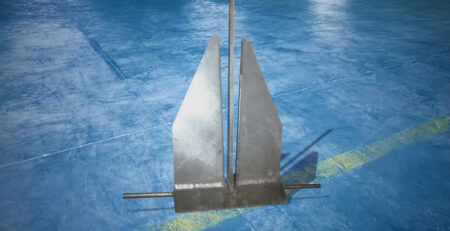

While the term sorbent boom is a broader category that can include booms for various liquids (water, chemicals), an oil absorbent boom is a specific type tailored for oil and hydrocarbon-based spills. The inner filling typically uses synthetic, hydrophobic sorbents, meaning they attract oil but repel water. The outer casing is often a durable fabric or mesh designed to hold the sorbent material while allowing oil to penetrate for absorption. This makes them a critical absorbent boom for oil spill scenarios.

How Do Oil Absorbent Booms Work?

The effectiveness of an oil absorbent boom lies in its combined containment and absorption capabilities.The containment mechanism is straightforward: the boom creates a physical barrier. On water, buoyancy keeps the boom afloat, forming a line on the water’s surface that prevents oil slicks from expanding. On land, booms are laid out to form a perimeter or channel, preventing the spill from flowing into unprotected areas.The absorption process happens within the boom’s structure. The internal sorbent materials, commonly made of polypropylene, are designed to be oleophilic – they have a strong affinity for oil. Crucially, these sorbents are often hydrophobic, meaning they resist or repel water. This allows the boom to selectively soak up oil (https://econadin.com/en/oil-only-absorbents-hydrophobic-spill-solution/) from the spill surface or within the contained area, leaving water behind. The boom continues to absorb oil until the internal material is saturated. Once saturated, the boom becomes less effective and must be retrieved and replaced with a fresh one. Booms are typically designed with connectors, allowing multiple sections to be quickly linked together. This feature enables responders to create continuous barriers of any necessary length to effectively manage larger spills or complex containment areas.

Types and Applications of Floating Absorbent Booms

Oil absorbent booms are designed with specific environments and spill scenarios in mind, addressing both land and water applications relevant to businesses.One common type is the floating absorbent boom. These are specifically engineered for use on water bodies like rivers, lakes, harbors, ponds, and coastal areas. Their construction includes buoyant elements – such as internal foam, solid floats, or sometimes inflatable sections – that keep them afloat on the water surface. This buoyancy ensures they form an effective barrier to contain spills on the water while the internal materials absorb the oil.Land-based booms, sometimes called socks or pillows depending on shape, serve different purposes on solid ground. They are used to surround machinery to catch leaks before they spread, line ditches or drains to protect waterways, or create perimeters around spills on factory floors, garages, or outdoor areas to absorb the liquid and prevent migration.Businesses may encounter variations in design, including:

- Different diameters and lengths available to match the potential spill volume and the size of the deployment area.

- Outer mesh or casing materials that can affect durability, UV resistance, or how quickly liquids reach the inner sorbent.

- Various types of internal sorbent materials, each with slightly different absorption capacities and rates.

- Quick-connect systems that allow boom sections to be rapidly joined together in an emergency.

Understanding the different types available is essential to selecting the most appropriate solution for a specific spill risk or environment your business faces.

Why Use Oil Absorbent Booms for Oil Spill Cleanup?

Using oil absorbent booms as a primary oil spill cleanup boom offers several key benefits for businesses managing potential or actual spills.Their most crucial role is preventing the spread of the spill. By forming a physical barrier (https://econadin.com/en/oil-spill-containment-booms-guide/), booms limit the area affected by the oil, which is fundamental in controlling the situation and preventing wider environmental harm or damage to property.Environmental protection is a significant advantage. By containing and absorbing oil, booms help protect sensitive areas like wildlife habitats, wetlands, shorelines, and water intake points from contamination. This minimizes the ecological impact of a spill.Booms offer rapid response capability. They are typically lightweight, easy to transport, and simple to deploy and retrieve, even with limited personnel. This makes them ideal for quick emergency response situations where getting control of the spill immediately is critical.Cost-effectiveness is another major benefit. Containing and absorbing a spill early with booms is significantly less expensive and less complex than attempting to clean up oil that has spread over a large area or seeped into difficult-to-access locations. Early intervention reduces cleanup costs substantially.Finally, having and using oil absorbent booms helps businesses meet environmental regulations. Demonstrating proactive spill preparedness and effective response during an incident shows due diligence, which can help avoid hefty fines, legal issues, and negative publicity associated with environmental non-compliance.

Choosing the Right Absorbent Boom for Your Needs

Selecting the correct absorbent boom for oil spill preparedness or response requires considering several factors specific to your business and potential risks.First, consider the type of liquid you need to manage. Are you primarily concerned with oil or other hydrocarbons? Oil-specific sorbent booms are ideal here. If you might encounter a wider range of liquids (water-based, mild chemicals), a universal sorbent might be necessary, but for oil spills, dedicated oil sorbents are more effective as they repel water.The environment where a spill might occur is critical. Is the risk on land (factory floor, garage, around tanks) or on water (near drains, ponds, loading docks)? For water, a floating absorbent boom is essential. For water deployments, also consider factors like potential currents, wave action, and water depth, as these can affect boom performance and required features.The potential size and volume of a spill will dictate the required length and diameter of the booms needed. Larger potential spills require more boom length to create a sufficient barrier and potentially larger diameter booms for greater absorption capacity.Consider the duration of deployment. Are you planning for emergency response that requires rapid, short-term use, or for preventative, long-term placement around equipment or drains? This can influence the required durability and UV resistance of the boom materials.Finally, consider the ease of deployment and storage. Can your available personnel easily deploy the booms quickly in an emergency? Do you have adequate space to store the necessary quantity of booms on-site, ensuring they are readily accessible when needed?

Oil absorbent booms are an indispensable component of any business’s spill response plan. They are a highly effective tool for oil spill cleanup, providing crucial containment to prevent spread while simultaneously absorbing the hazardous liquid. As a specific type of sorbent boom, the absorbent boom for oil spill scenarios is tailored to handle hydrocarbons efficiently. Investing in the right oil absorbent booms is a responsible and proactive step for environmental protection and regulatory compliance, making them a necessary asset for businesses aiming to mitigate the risks associated with oil spills.