What is an Oil Belt Skimmer? Your Guide

Dealing with oil contamination on water surfaces is a common problem in many industrial settings. Tanks, sumps, and pits can quickly collect a layer of free-floating oil, hydraulic fluid, or other hydrocarbons. This oil causes issues with processes, fluid lifespan, and environmental compliance. Fortunately, there is a highly effective mechanical solution: the oil belt skimmer. This guide will explain what an oil belt skimmer is, how it works, its key benefits for businesses, and where it’s commonly used to help you understand its significant value.

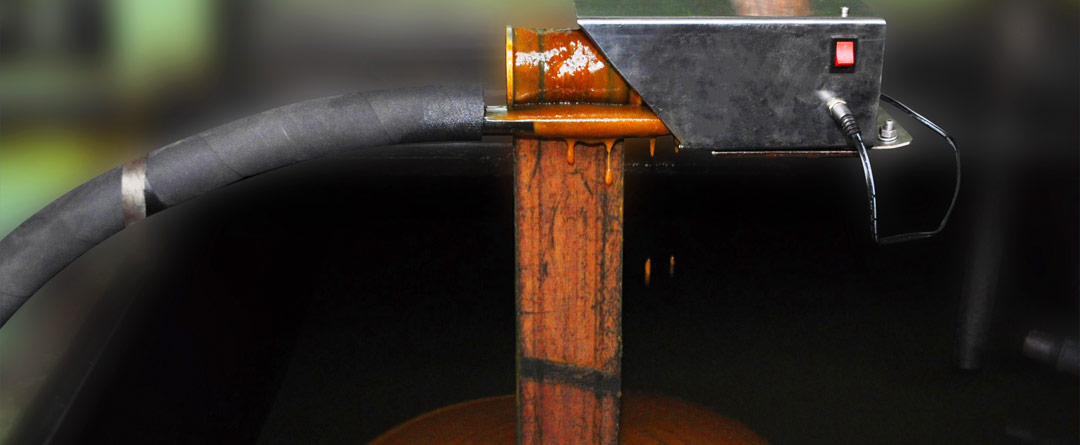

An oil belt skimmer, also known as a belt type oil skimmer, is a piece of equipment designed specifically to remove oil floating on the surface of a liquid. Its defining feature is the use of a continuous loop of specialized belt material. This belt dips into the contaminated liquid and travels back up.

The primary function of this belt type oil skimmer is the efficient removal of free-floating oils and hydrocarbons. It works in various industrial settings, including tanks, sumps, pits, and separators. It’s a key component used in many different industrial oil skimmer systems across countless industries.

How a Continuous Belt Skimmer Works

The basic principle behind a continuous belt skimmer is simple yet effective. The belt material is oleophilic, meaning it attracts oil but repels water. This property is key to the separation process.

Here’s how it works:

- The belt moves down into the liquid, passing through the oil-water interface.

- As the belt travels, it picks up a layer of oil that sticks to its surface. Water is largely left behind.

- The belt then travels upwards towards the head pulley at the top of the skimmer.

- As the belt passes over the pulley, scrapers remove the oil from both sides of the belt.

- The removed oil falls into a collection trough or reservoir, separating it from the water.

This continuous process effectively pulls the oil off the surface, leaving cleaner water behind.

Why Use an Industrial Oil Skimmer?

Using an industrial oil skimmer offers numerous benefits for businesses that deal with oil-contaminated water or process fluids.

- Highly Efficient Oil Recovery: These systems are very good at separating free-floating oils. They can often remove oil to a level that allows the water to meet disposal or reuse standards, preventing expensive fines.

- Significant Cost Savings: Removing oil from water reduces the volume of contaminated liquid that needs expensive disposal. It also extends the life of valuable process fluids, like coolants and wash water, saving money on replacement costs.

- Extended Fluid Lifespan: Tramp oil in coolants causes them to degrade faster, leads to unpleasant odours, and reduces machining performance and tool life. An industrial oil skimmer removes this oil, keeping fluids cleaner and effective for longer. This is a major part of oil recovery.

- Environmental Compliance and Safety: Meeting strict regulations for wastewater discharge is critical. Oil skimmers help businesses comply by removing oil before discharge. Removing oil from floors also reduces slip hazards, improving workplace safety. By removing oil from process fluids, they can also reduce oily mist, improving air quality.

- Reduced Downstream Costs: Removing oil early in the process reduces the load on later filtration systems. This means less frequent filter changes, lower maintenance costs, and improved overall system efficiency.

These benefits highlight why an industrial oil skimmer is a smart investment for managing oil contamination.

Common Applications for Oil Recovery Belt Systems

An oil recovery belt system is versatile and used in many different industrial settings where oil and water mix. Here are some common applications:

- Machining Coolant Sumps: This is a very common use. Oil recovery belt systems remove contaminant oils (often called tramp oil) that leak into machine tool coolants. This preserves the quality and life of the coolant and the machine tools.

- Parts Washers: Keeping wash water clean is essential for effective parts cleaning. Belt skimmers remove oils that are washed off parts, ensuring the water remains clean for better results.

- Wastewater Treatment Plants: Belt skimmers are often used as a pre-treatment step. They remove surface oil before the water goes through other, more complex treatment processes.

- Outdoor Ponds, Sumps, and Pits: These systems are effective for skimming oil from stormwater runoff, settling ponds, or accidental spills in outdoor environments. They can handle varying water levels.

- Manufacturing Processes: Any manufacturing area where hydraulic oil leaks, lubricating oil runoff, or processing oils come into contact with water or aqueous solutions can benefit. This highlights the versatility of the industrial oil skimmer in general manufacturing.

These examples show how valuable an oil recovery belt system can be across a wide range of industries.

Choosing the Right Oil Belt Skimmer

Selecting the best oil belt skimmer for your specific needs requires considering several critical factors.

- Tank or Area Size and Shape: The size and shape of the tank, sump, or pit where the oil is collecting will determine the required reach and mounting type of the skimmer.

- Type and Viscosity of Oil: Different types of oil (hydraulic fluid, cutting oil, grease) and their viscosity affect how well they stick to the belt. Some belt materials work better for different oil types.

- Oil Removal Rate: How fast is oil accumulating on the surface? This determines how much oil the skimmer needs to be capable of removing per hour to keep the surface clean.

- Available Space and Vertical Lift: Consider where the skimmer can be installed. How much vertical distance does the oil need to be lifted from the liquid surface to the collection point?

- Environmental Conditions: Factors like liquid temperature, pH levels, and the presence of solids or aggressive chemicals can affect the choice of skimmer materials, especially the belt.

Carefully considering these factors ensures you select an oil belt skimmer that will perform reliably and effectively for your application.

Conclusion

Oil contamination is a persistent challenge for many businesses. Oil belt skimmers offer a proven, reliable, and efficient mechanical solution for separating oil from water or other process fluids.

As a crucial component in industrial oil skimmer and oil recovery belt system applications, they provide substantial benefits. Implementing an oil belt skimmer leads to increased operational efficiency, significant cost savings through reduced waste disposal and fluid replacement, improved environmental compliance, and a safer workplace. For businesses dealing with unwanted surface oil, a belt skimmer is a valuable tool for effective oil management.