Marine Security Barriers are a versatile structure designed to safeguard critical maritime facilities against waterborne attacks. Featuring a modular design with identical, interchangeable components, these water security barriers allow for easy replacement in the event of damage or routine maintenance.

- Port security solutions

- Shipyard perimeter protection

- Maritime security fencing

- Oil terminal security barriers

- Nuclear power plant water barriers

- LNG facility security water barriers

- Hydropower plant defence

- Coastal security barriers

- Bridge protection barriers

- Military-grade maritime barriers+

All of our floating security barriers are equipped with a vessel intrusion prevention system, enhancing the protection of critical marine infrastructure.

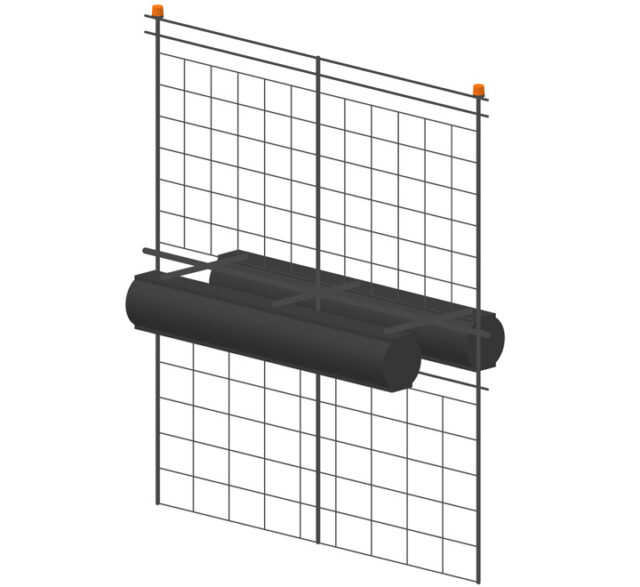

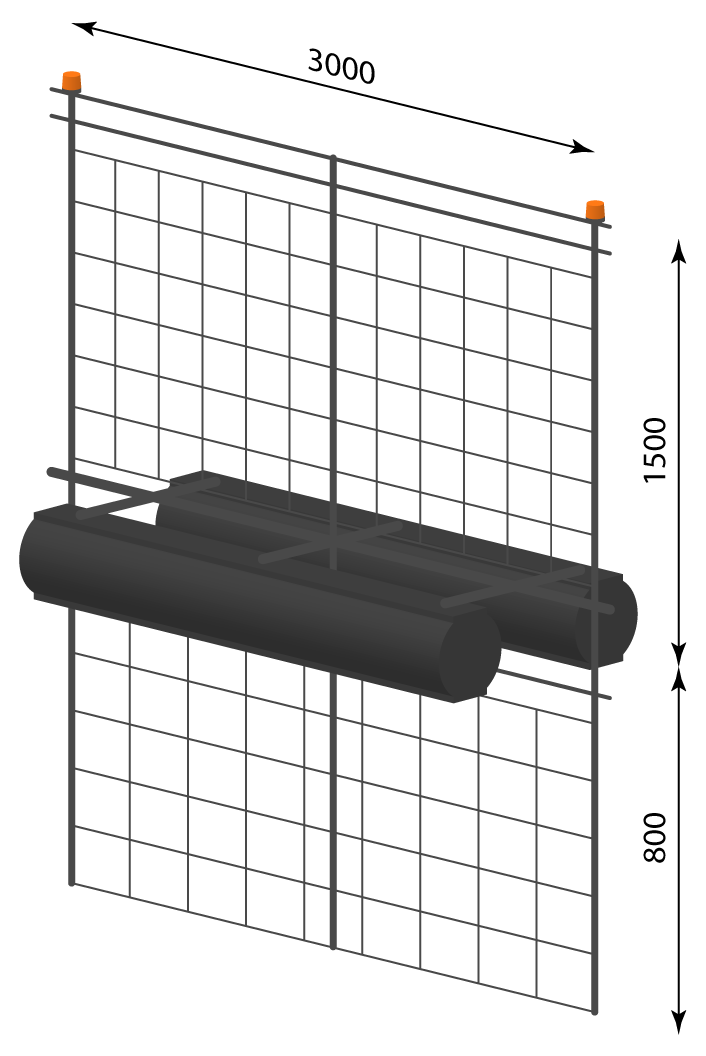

The design of maritime security barriers consists of

1. Robust outer frame.

Constructed using H-beams, the outer frame offers exceptional rigidity to wave forces and sudden wind gusts. To enhance durability, critical connection points that experience bending loads are reinforces with stiffeners and, in some cases additional spacers, ensuring greater stability at attachment points of our water-based security systems.

The outer frame is exceptionally strong, making it an effective boat deterrent barrier capable of stopping not only water drones but also small vessels.

All connections between the frame components and floats of our high-security barriers are secured using high-strength bolted fasteners. The metal construction incorporates corrosion-resistant stainless stell hardware of Class A2, ensuring long term durability in marine environment.

The central steel I-beam is designed to withstand significant torsional and bending loads, ensuring uniform distribution of tensile forces along the entire length of each barrier section for maximum structural integrity.

2. Two floating elements of the marine security barriers .

Attached to both sides of the outer frame, they maintain the buoyancy of the structure and serve as a anti-terrorism marine barriers effectively against marine drones and small crafts.

Each floating element is constructed from thick-waled, impact-resistant, and water-resistant polyethylene, offering maximum resistance to ultraviolet radiation for long-term durability.

Inside the polyethylene float, reinforcement in the form of steel is used, which evenly distributes the load in the places where the floats are attached to the frame. This reinforcement also reduces horizontal and vertical loads from wave action on the metal structure of the frame, allowing it to withstand variable loads.

The internal volume of the floating elements is filled with polyurethane foam with a low water absorption coefficient.

Thanks to this, even in the event of mechanical damage to the outer shell of the float, the element retains buoyancy. That makes our fencing as a perfect part of harbour defence solution.

The floating elements are made of polyethylene material for general use in rotational moulding processes and are suitable for applications that require a combination of rigidity and impact strength, as well as low deformation and excellent processability.

Polyethylene filling material is fully thermally and UV- stabilized, ensuring a wide processing range, good colour retention and a long service life.