The Essential Guide to Oil Containment Fence Booms

Effective oil spill containment is critical, especially in sensitive or controlled environments like harbors, marinas, or industrial facilities. Even small spills in these areas can cause significant environmental harm or disrupt operations. This is where the oil containment fence boom steps in as a specialized, highly effective solution. Its unique structure sets it apart, offering distinct advantages for specific containment challenges.

An oil containment fence boom is designed for easy storage, rapid deployment due to its lightweight nature, and optimal suitability for calm water, protected harbors, and various industrial settings. Its stability and ease of handling are paramount, making it a reliable choice for businesses focused on proactive spill management.

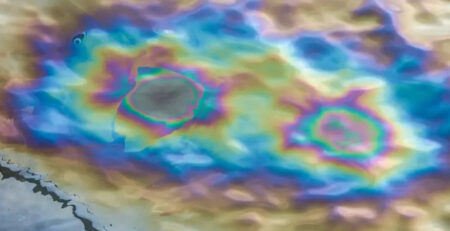

A fence boom is a type of containment boom that features a rigid, upright barrier, often described as a ‘fence,’ extending both above and below the water surface. Its construction typically involves buoyant flotation chambers and weighted skirts, integrated with vertical stiffeners. These internal components give the boom its distinctive upright shape, much like other solid flotation booms.

Unlike more flexible options such as inflatable booms or curtain booms, a fence boom maintains a consistent vertical profile. Flexible curtain booms might sag or deform under pressure, but the fence boom’s inherent rigidity ensures it acts as a continuous, reliable barrier. Its primary purpose is the efficient containment of surface oil spills, preventing their spread, and guiding them for recovery in specific, calmer water conditions where its design advantages are maximized.

Key Features and Advantages

Vertical Oil Boom Structure and Stiff Oil Boom Performance

The effectiveness of an oil containment fence boom lies in its internal vertical oil boom elements, which are essentially stiffeners or solid floats. These components are vital for maintaining the boom’s upright position and structural integrity. They ensure a consistent freeboard (the part of the boom above water) and draft (the part below water).

These rigid components contribute to a stiff oil boom that strongly resists collapse, twisting, or submersion. This remains true even when faced with minor currents, boat wakes, or the weight of collected oil. This rigidity maximizes effective freeboard, preventing oil from washing over the top. It ensures the boom remains an effective barrier, helping to maintain boom shape for continuous and reliable containment. The enhanced stability minimizes boom ‘ponding’ or ‘dishing,’ which can occur with less rigid booms, making it more reliable for long-term deployments in suitable conditions.

Lightweight Spill Boom for Rapid Deployment and Handling

The lightweight spill boom design offers significant advantages for manageability. These booms often utilize durable yet low-density materials in their construction, greatly reducing the overall weight per section. This characteristic simplifies handling and transport.

Their reduced weight allows for quicker mobilization and deployment by smaller crews, often without the need for heavy machinery or specialized vessels. The compact, often stackable, nature of these booms leads to a reduced storage footprint. This makes them ideal for facilities with limited space or for pre-positioning at high-risk locations. This agility is a key benefit for small and medium-sized businesses, enabling rapid emergency response where time is critical.

Optimal Performance in Specific Environments

Oil containment fence booms are ideally suited for calm waters, protected harbors, marinas, inland waterways, and various industrial applications where wave action and strong currents are minimal. While their rigidity is a significant advantage, it also means they are less flexible for high-energy, open water environments.

Their effectiveness shines in preventing spills from spreading in areas with minimal wave action or strong currents. The consistent vertical profile of these booms is highly effective at containing oil in controlled settings, making it a reliable choice for both spill prevention and immediate response.

Ideal Applications of Oil Containment Fence Booms

Oil containment fence booms are versatile tools for various spill prevention and response scenarios in controlled water environments:

- Harbor and Port Protection: They are commonly deployed around docks, fuel transfer stations, and alongside vessels. This helps contain potential spills during bunkering operations or cargo loading and unloading.

- Industrial Facilities: These booms can be installed permanently or temporarily around power plants, manufacturing sites, wastewater treatment ponds, and other industrial areas. They help manage oil runoff or accidental discharges, preventing wider contamination.

- Marinas and Recreational Boating Areas: They safeguard sensitive aquatic environments from spills originating from pleasure crafts or maintenance activities. This protects marine life and water quality.

- Containment During Maintenance Operations on Calm Water: Oil containment fence booms are excellent for creating isolated work zones for vessel repair, dredging, or infrastructure maintenance. They prevent contaminants from spreading into the wider water body.

- Emergency Response for Smaller, Contained Spills: They serve as a first line of defense for immediate deployment around minor leaks or spills in controlled environments. This helps prevent minor incidents from escalating into larger environmental problems.

Deployment and Maintenance Best Practices

Proper deployment and maintenance ensure the longevity and effectiveness of oil containment fence booms. For deployment, pre-planning is essential. This includes identifying optimal anchoring points and ensuring proper tension to maximize containment without overstressing the boom. The boom should be deployed in a way that creates a secure barrier, preventing oil from escaping.

Regular cleaning is crucial. After use, booms should be rinsed with fresh water and mild detergents to remove oil and debris. This prevents material degradation and ensures readiness for future deployments. Routine inspection is also vital. Check for tears, punctures, and wear on connectors. Inspect the integrity of stiffeners and flotation chambers. Any damage should be repaired promptly.

For proper storage, keep booms clean, dry, and protected from direct UV exposure and extreme temperatures. Storing them in a cool, dark place will ensure their longevity and readiness for immediate deployment when needed.

Why Choose an Oil Containment Fence Boom for Your Needs?

Choosing an oil containment fence boom offers a unique value proposition for businesses. It combines the robust barrier of a stiff oil boom with the manageability of a lightweight spill boom. This makes it an ideal choice where stability, consistent containment, and ease of use are paramount.

These booms are particularly cost-effective and efficient for specific containment challenges in calm, controlled environments. Their durability and ease of maintenance contribute to a lower total cost of ownership compared to less specialized solutions. For small and medium-sized businesses, an oil containment fence boom represents a smart investment. It supports proactive spill prevention and establishes efficient rapid response capabilities in suitable settings, protecting both assets and the environment.

Conclusion

The oil containment fence boom stands out as a highly effective solution for managing oil spills in calm water, harbor, and industrial environments. Its unique design, featuring a rigid, upright barrier, ensures consistent and reliable containment. This specialized boom offers significant advantages, including a compact, lightweight design for rapid deployment and enhanced stability for long-term effectiveness. It is a vital tool for proactive spill prevention and rapid response, offering unique benefits for specific containment requirements. For any small and medium-sized business prioritizing environmental protection and operational readiness in controlled aquatic settings, considering an oil containment fence boom is a strategic decision that offers both peace of mind and practical utility.