Addressing Comprehensive Oil Spill Control: Oil absorptive boom with skirt

Cleaning up oil spills is a critical challenge. It’s not just about scooping up oil floating on top of the water. Preventing the oil from spreading below the surface is just as important. This is especially true in moving water or near sensitive natural areas. A standard floating barrier might not be enough. The Oil absorptive boom with skirt is a special tool designed for this tough job. It uniquely combines soaking up oil on the surface with a physical wall that goes down into the water. This post will look at what this advanced boom does, why it’s helpful, and where businesses can use it to control oil spills effectively.

Simple floating barriers, or oil spill containment booms, work well for keeping oil on the surface in calm water. But they have limits. Oil can easily sneak under them in certain conditions. Water movement, like waves or currents, can pull oil droplets under the boom. This is called entrainment. Oil can also flow down the front of the boom and escape underneath. This is known as drainage failure. undetected sub-surface oil migration causes big problems. It spreads pollution much wider and harms more of the environment. This shows a real need for a barrier that goes deeper than just the water surface. Oil can also escape below the skirt through drainage failure. This highlights why an oil spill boom with barrier below the surface is needed.

What is an Oil absorbent boom with skirt?

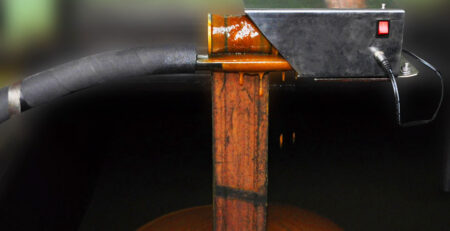

An Oil absorbent boom with skirt is a special type of containment boom. It does two main things at once. First, it absorbs oil from the water surface. Second, it physically blocks the oil from moving below the surface. It has two main parts. The top part is absorbent. It is made to soak up oil. The bottom part is the skirt. This is a weighted curtain that hangs down into the water. The skirt works like a physical wall under the water. It often has a ballast chain along the bottom edge. This chain helps the skirt hang straight down and stay steady in the water. The absorbent part uses materials like polypropylene. These materials are oleophilic, meaning they attract oil. Oil-only absorbents are designed to selectively soak up oil and hydrocarbons while repelling water. This is different from regular containment booms that only act as a floating wall. This combination makes it a powerful skirted sorbent boom. Oil absorbent booms are vital for containing and absorbing oil spills, preventing environmental damage and financial losses.

Key Features and Benefits for Commercial Use:

An Oil absorbent boom with skirt offers several advantages that are very useful for businesses dealing with potential oil spills.

Dual Functionality

The biggest benefit is that it does two jobs at once. It absorbs oil off the top of the water and stops oil from going under the surface. This provides a more complete and efficient way to handle spills compared to using separate items for soaking and blocking.

Superior Containment

The skirt going below the water makes the barrier much better at holding oil in place. It acts like an oil spill boom with barrier. This stops oil from getting out from under the boom when there are currents, tides, or waves. This is very important for businesses. If containment fails, cleanup costs can be very high.

Absorption Capability

The absorbent top part of the boom actively soaks up oil. This helps remove the oil from the water itself, not just contain it. This makes cleanup easier and makes the water look cleaner faster. This soaking action is a key feature of a skirted sorbent boom. It’s often called an absorbent containment boom because it combines soaking and holding.

Versatility

These booms are good for many different water conditions and places. You can use them in calm harbors, near coastlines with waves, in rivers, and in industrial ponds. They work well because they both soak up oil and provide strong containment.

Ease of Deployment & Connection

For quick response, these booms are made to be easy to use. They have strong connectors that hook multiple boom sections together quickly. This lets you make the barrier as long as you need it. They are also designed to be handled easily when you put them in the water and when you take them out.

Durability

These booms are built tough. They use materials that can stand up to oil, chemicals, sunlight, and harsh water conditions. This means they are reliable and last a long time, even in tough industrial or marine settings.

Applications: Where Oil absorptive booms with skirts are Essential

The dual protection offered by Oil absorptive booms with skirts makes them vital in many commercial and industrial areas.

- Marinas, Ports, and Fueling Docks: These places have boats that can cause spills. Boat traffic also creates wakes and turbulence. The skirt helps stop oil from being pushed under the boom by this activity.

- Industrial Facilities: Plants located near water often have pipes releasing water. If there’s an accidental oil release, these booms can be placed to stop it from spreading into the main waterway.

- Construction Sites: Building near rivers or lakes carries the risk of spills from machines or materials. A skirted boom protects sensitive water habitats nearby.

- Power Plants and Refineries: These sites often handle large amounts of oil. Skirted booms are crucial for containing spills in cooling ponds or along waterfronts, managing currents and water level changes.

- Critical Infrastructure: Bridges, terminals, and other key structures near water need protection from spills that could disrupt operations or cause environmental harm.

In these locations, the skirt is very useful. It helps manage changing water levels from tides. It works against currents trying to pull oil away. It stops oil from escaping under the boom due to boat wakes. It protects sensitive natural areas. It also helps businesses follow rules that require stopping all oil from leaving their site.

Choosing the Right Skirted Boom

Selecting the correct skirted sorbent boom is important for businesses. Here are key things to think about:

- Size: How long and wide does the boom need to be? This depends on how big a spill might be and the area you need to protect.

- Skirt Depth: How deep does the water get? How strong are the currents? The skirt needs to go deep enough to be an effective barrier.

- Materials: What type of oil might spill? What are the environmental conditions (saltwater, chemicals)? Choose materials that can handle these.

- Connections: How easy is it to connect sections? Are the connectors strong and reliable? This is key for fast setup.

- Absorption Capacity: How much oil can the absorbent containment boom soak up? Make sure it can handle the potential spill volume.

- Buoyancy: Does the boom float well, even when it has soaked up oil or when the skirt is in turbulent water?

Thinking about these points helps ensure you pick a boom that will work effectively when you need it most.

Conclusion

Oil absorbent booms with skirts offer a powerful solution for oil spill containment. They are unique because they provide a dual action. They clean up oil on the surface while also creating a physical barrier below the water. This directly solves the problem of oil sneaking under standard booms. For businesses and facilities near water, having the right Oil absorbent boom with skirt is a smart investment. It means you are prepared for spills, protecting the environment, and keeping your operations running smoothly.