Effective Oil Spill Cleanup: Solutions, Methods, and Products

The critical need for effective oil spill cleanup cannot be overstated. This essential process involves mitigating the adverse effects of an accidental release of oil into the environment. Its immediate and critical importance extends to both ecological health and operational safety. Oil spills present a dual challenge: protecting fragile ecosystems from contamination and ensuring the safety of personnel and facilities. An effective and rapid response to an oil spill requires both comprehensive knowledge of cleanup methodologies and access to the right tools and products. This blog post serves as a complete guide, covering essential solutions, proven methods, and the specific absorbent and containment products necessary for rapid response across various scenarios.

Understanding Oil Spills: Types and Their Impact

An oil spill constitutes any accidental discharge of oil, ranging from small, unnoticed leaks to catastrophic discharges of crude oil or refined petroleum products. These spills occur in diverse contexts, each presenting unique challenges.

- Industrial Oil Spill Control: Spills in manufacturing plants, workshops, refineries, storage facilities, and power generation sites demand specific strategies. Unique challenges arise from diverse floor types like concrete and asphalt, proximity to machinery, and the potential presence of other chemicals or hazardous materials. Effective industrial oil spill control often requires heavy-duty absorbents and robust containment solutions.

- Marine Spill Response: Spills occurring in oceans, rivers, lakes, and port areas introduce significant complexities. Factors such as water currents, tides, and wave action complicate cleanup efforts. A marine spill response operation faces a substantial threat to marine wildlife, coastal habitats, and vast areas, necessitating specialized equipment and rapid deployment.

- Workplace Spill Containment: Smaller, more localized spills frequently happen in office environments, laboratories, commercial kitchens, or general retail settings. The importance of quick, safe handling is paramount to prevent slips, falls, and localized contamination. These incidents are often handled efficiently with readily available spill kits designed for workplace spill containment.

Unaddressed or poorly managed oil spill cleanup operations lead to severe potential consequences. These include extensive environmental consequences such as habitat destruction and direct wildlife impact, significant safety risks like fire, explosion, and hazardous fumes, and severe financial repercussions encompassing high cleanup costs, hefty fines, and lengthy litigation. Additionally, legal liabilities from regulatory non-compliance can be substantial.

The Comprehensive Oil Spill Cleanup Process: From Containment to Restoration

The oil spill cleanup process is a multi-step operation designed to minimize damage and restore affected areas.

Immediate Assessment & Safety First

The very first step in any spill scenario is ensuring the safety of responders by donning appropriate personal protective equipment (PPE). Following this, a rapid assessment of the spill’s type (e.g., fuel, crude oil), estimated size, and potential hazards is crucial. This initial evaluation informs all subsequent actions and determines the resources needed for an effective oil spill cleanup.

Oil Spill Containment: The First Line of Defense

Oil spill containment is a critical first line of defense. Its role is to prevent the spill from spreading, thereby limiting environmental damage and simplifying subsequent cleanup efforts. Common containment methods include deploying floating booms on water to encircle the spill, establishing temporary barriers or berms on land to block its flow, or creating dikes around the spill’s perimeter to restrict its movement. The speed and strategic deployment of oil spill containment measures are paramount, as every minute counts in preventing wider contamination.

Absorption and Removal Techniques

Various methods are employed for active oil removal. For smaller, contained spills, highly absorbent pads, socks, and pillows are used to soak up the oil. Over larger areas, loose granular absorbents can be distributed. Mechanical recovery techniques are crucial for more substantial spills. This includes using specialized skimmers to separate oil from water, particularly vital for marine spill response, or industrial vacuums to collect pooled oil, which is highly relevant for large-scale industrial oil spill control operations. Other advanced techniques, like bioremediation (using microbes to break down oil) or controlled dispersion (using chemicals to break down oil), may also be considered, though often with strict regulatory caveats due to their potential environmental impacts.

Proper Waste Disposal

The absolute necessity of regulatory compliance, such as adhering to EPA and OSHA guidelines, cannot be overstated when it comes to proper waste disposal. Safe handling procedures are essential for all contaminated materials, including used absorbents, recovered oil, and soiled equipment. These materials must be transported and disposed of at approved facilities to prevent any form of secondary contamination.

Site Restoration and Monitoring

Post-cleanup steps include thorough cleaning of affected surfaces and, where necessary, soil remediation. Ongoing environmental monitoring is crucial to confirm the successful removal of contaminants and to support the long-term ecological recovery of the affected area.

Essential Products and Solutions for Rapid Oil Spill Cleanup

Having the right tools is as important as understanding the process for effective oil spill cleanup.

Absorbents

Different types of absorbent products are available, each suited for specific applications. Highly absorbent pads and rolls are ideal for wiping surfaces and smaller spills. Absorbent socks are designed for containing perimeter spills and directing flow. Pillows are effective for soaking up larger volumes of oil. These products vary in application, from compact solutions found in workplace spill containment kits to bulk industrial absorbents required for major incidents.

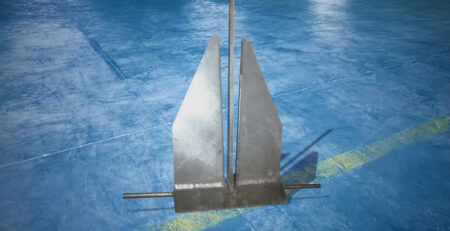

Containment Barriers

Essential containment barriers are crucial for effective oil spill containment. These include absorbent booms, which can be deployed on water or land, flexible dikes, and robust berms. Their varied designs cater to different environments and spill scenarios, ensuring the spill remains isolated.

Spill Kits

Pre-assembled, organized spill kits are invaluable for rapid response. These kits are tailored for specific environments and spill types. They range from small, portable workplace spill containment kits (e.g., for vehicles or offices) to larger industrial oil spill control kits (for factories or warehouses). Specialized marine response kits are also available, specifically designed for waterborne incidents and comprehensive marine spill response.

Personal Protective Equipment (PPE)

Essential gear for responders includes oil-resistant gloves, protective eyewear, respirators (if hazardous fumes are present), chemical suits, and safety footwear. This PPE ensures maximum safety during oil spill cleanup operations.

Specialized Equipment

Larger, more complex equipment is crucial for managing significant incidents. This includes mechanical skimmers for separating oil from water, high-capacity pumps for transferring liquids, and portable containment pools. These tools are crucial for effective marine spill response and large industrial incidents. To see spill response equipment in action, consider watching demonstrations of how these tools are deployed during cleanup operations.

Choosing the Right Oil Spill Cleanup Strategy

Developing an effective oil spill cleanup strategy requires careful consideration of several factors. These include the type of oil involved (e.g., light fuel vs. heavy crude), the volume of the spill, the specific location (e.g., open water, concrete floor, soil), the type of surface affected, and the environmental sensitivity of the area. It is crucial to have a robust and pre-defined oil spill containment plan in place. This plan should clearly dictate roles, responsibilities, and emergency procedures, allowing for a swift and coordinated response, thereby maximizing the effectiveness of the oil spill cleanup.

Prevention: The Best Form of Oil Spill Control

While effective cleanup is vital, proactive measures represent the most effective form of oil spill control. This includes regular maintenance of machinery and storage tanks, strict adherence to proper storage protocols for oil and other hazardous liquids, and comprehensive employee training on both spill prevention and response. Strategic placement of oil spill containment products in high-risk areas is also a key preventive measure. Preparedness is invaluable, particularly for robust industrial oil spill control in manufacturing settings and diligent workplace spill containment practices in commercial environments. Prevention far outweighs the cost and damage associated with a spill.

Conclusion: Safeguarding Environments with Effective Oil Spill Cleanup

The overarching importance of quick, effective oil spill cleanup cannot be overstated. It is fundamental for protecting environments, ensuring safety, and mitigating significant financial and legal liabilities. Understanding the comprehensive cleanup process is as vital as having immediate access to the right tools and products. Businesses and organizations are encouraged to explore comprehensive solutions, invest proactively in appropriate oil spill containment products, and commit to regular training. Being thoroughly prepared for any spill scenario is essential for ensuring both regulatory compliance and strong environmental stewardship.