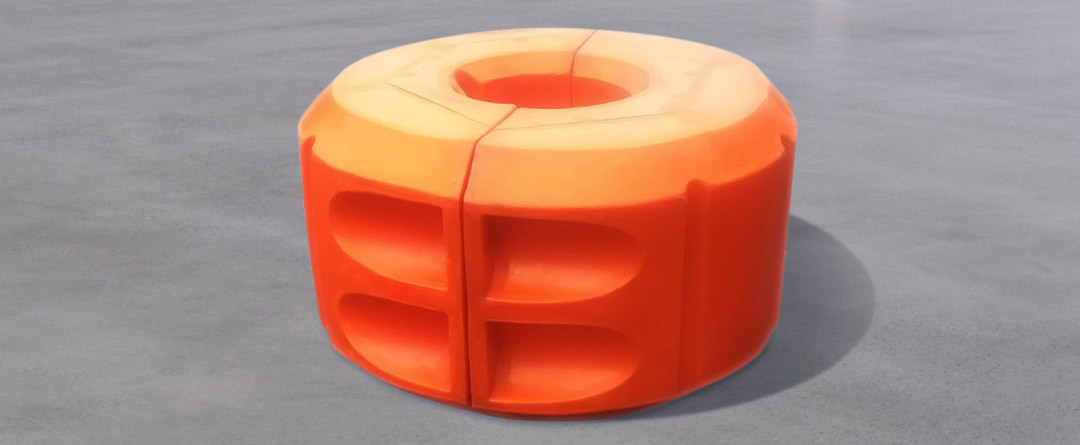

Buoys for slurry pipelines by “Econad” company

In the management and operation of slurry pipeline systems, ensuring the stability and functionality of pipelines is critical to maintaining efficiency and safety. Buoys for slurry pipelines play a vital role in these systems by providing the necessary support and flotation, helping to maintain the optimal position of pipelines in various environments. These specialized buoys are designed to withstand the harsh conditions often associated with slurry transport, including abrasive materials, varying pressures, and challenging weather conditions.

Buoys for slurry pipelines are engineered to keep pipelines afloat, preventing them from sinking or becoming misaligned. This is particularly important in environments where pipelines cross bodies of water or traverse marshy terrain. By keeping the pipelines buoyant, these buoys help to reduce wear and tear on the pipes, extend the lifespan of the system, and ensure the continuous, reliable flow of slurry materials.

Floats for slurry pipelines are another crucial component in these systems. They are designed to work alongside buoys to provide additional stability and support. These floats help distribute the weight of the pipeline more evenly, reducing stress on the structure and preventing sagging or bending. This is particularly important in long-distance slurry pipelines, where maintaining a consistent and stable alignment is key to preventing blockages and ensuring smooth operation.

In addition to buoys and floats, various accessories for slurry pipelines are available to enhance the performance and durability of these systems. These accessories include pipeline clamps, anchors, and protective coatings that help to secure and protect the pipeline in challenging environments. For example, pipeline clamps can be used to fasten the pipeline to the buoys and floats, ensuring that it remains securely in place. Protective coatings can be applied to the pipeline to prevent corrosion and wear, further extending the life of the system.